In all this evolution the key principles are addressed and basic instincts of protection being key.

We are living in unprecedented times and due to a pandemic most are spending more time at home not just for leisure and relaxation, but for work too. The recently rolled out vaccination programme gives us all hope, but there is no doubt that these challenging times have brought peoples appreciation of the important things in life, such as time with friends and family over materialistic possessions.

The energy crisis in the early to mid-1970s added to, and continues to validate our appreciation that we cannot rely on the earths existing resources for basic comfort goals.

At the A. Proctor Group (APG) we like to take account of the HAMM (Heat Air Moisture Movement) principles that looks at the effect of insulation type and placement along with the vapour permeability of the various layers. This leads to a balance of key factors producing a healthy building envelope that protects the occupants.

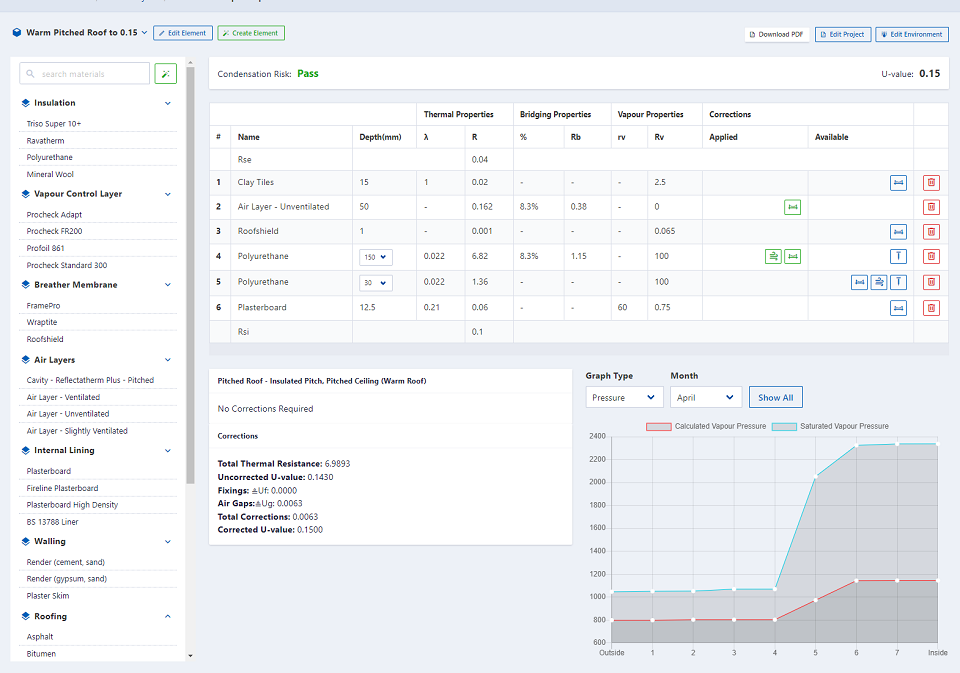

One of the features of balancing these principals can involve calculations to assess condensation and/or moisture risks. Glaser calculations can do this but can have limitations, which a WUFI calculation can help overcome e.g., rain and drying out of residual moisture in the construction. With a WUFI (BS EN 15026) calculation, it can be shown what effect differing performing VCLs can have on the structure and whether it is critical. It is difficult to argue that a VCL is not a good thing but similar to the first COVID-19 injection, a VCL should be used to reduce the moisture risks to acceptable levels but not be relied upon as the sole method of protection. Remember a VCL is a vapour CONTROL layer not as previously referred to in the antiquated terminology of a vapour barrier, that led to its over reliance.

Hygrothermal Assessment

Construction professionals have traditionally utilised the Glaser method to assess condensation risk. However, WUFI® software has been an enormous step forward for the industry in terms of condensation risk assessment. In contrast to the Glaser method, WUFI® calculations are ‘non-steady state’ simulations that constantly plots the movement of heat, air and moisture in a state of constant change relative to building usage, project aspect, and seasonality

WUFI® goes much further than Glaser by including other sources moisture such as ingress from the ground, worst-case scenario precipitation events, and the natural variation moisture content within individual building materials over time. As a result, the designer or contractor can simulate hour-by-hour condensation risk analysis over an infinite amount of time and projects optimised f longevity and the health and wellbeing of occupants

Introducing variable permeability in VCLs

The general use of a VCL (vapour control layer) along with a vapour-permeable membrane would, in theory, show a well protected building envelope. However, studies carried out by the Institute for Building Physics, Stuttgart, h demonstrated that if the VCL is not sealed correctly, or is punctured, this can have a damaging effect resulting in high levels of vapour getting into the building envelope.

Traditional, high resistant vcls can prevent drying out in any direction, other than to the outside, whereas a low resistance vcl could allow too much vapour to pass into the structure. In the UK, the vapour drive generally means that vapour will pass from inside to outside, however during warmer periods there will be times that this vapour drive could be reversed. Based on extensive research and development, the A. Proctor group developed Procheck Adapt, specifically designed to protect the building fabric from the potential risks of condensation whilst providing the added benefit of serving as an effective airtight barrier.

Thanks to its unique design, the membrane offers variable permeability that adapts to changes in humidity levels and allows the structure to dry out in the summer and sunny days in spring and autumn while protecting it from moisture overload in the winter and cold, wet days.

This high-performance intelligent vapour control layer adapts its vapour resistance to the environment, i.e. vapour tight in the winter and vapour open in the summer. The incorporation Procheck Adapt ensures that the building fabric is protected from damaging moisture levels during cold, wet periods a allows the fabric to dry out effectively in warmer, dri times.

Further, the translucent structure of Procheck Adapts eases fixing to structural frames and, in conjunction with i integral tape, allows for a fast installation time.

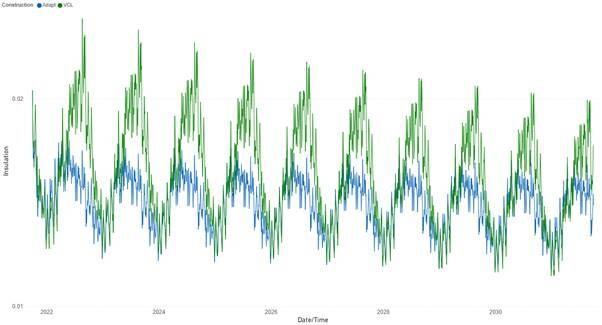

WUFI® assessment of Procheck Adapt

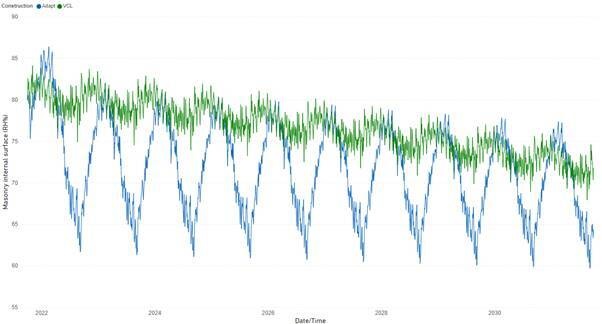

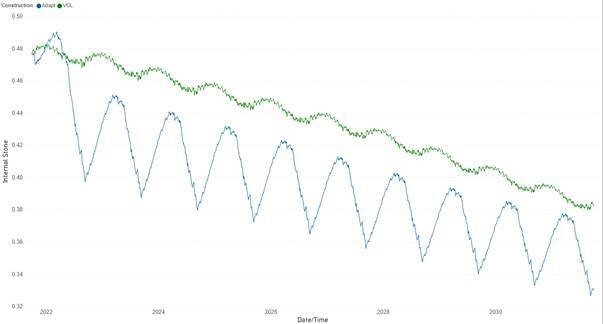

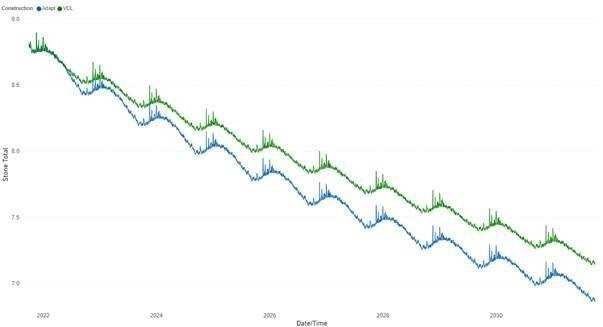

The graphs here show the results of a hygrothermal simulation, run for ten years, using 500mm of Sandstone (represented as 30% stone, 40% mortar, 30% stone (150, 200, 150mm)) provide an accurate mortar composition. First, Sandstone was insulated using 120mm of mineral wool after a 5 airspace. Next, the Vapour Control Layer (VCL) installed internally, followed by a 12.5mm plasterboard. The assessment measured the performance of two vapour control layers, Procheck Adapt and the higher vapour resistant Procheck A2.

The first graph displays the relative humidity of the internal surface of the stone. Humidity begins at 48%, assuming a relatively high moisture content for the masonry onto which it is applied. In both cases, this reduces over time. The green shows a standard VCL (with a vapour resistance of 1500MNs/g), which reduces towards a roughly stable equilibrium year- round. The blue line shows the relative humidity of the surface using Procheck Adapt. In the case of the humidity of the surface with Procheck Adapt, this is consistently lower than the case using a standard vapour control layer, as the masonry is more able to dry in summer and is protected against winter condensation.

Procheck Adapt is a Certified Passive House component, tested by the Passive House Institute, and is suitable for a variety of commercial and residential applications and provides airtightness to the structure and vapour control.

Graphs 2 and 3 show the stone’s water content, especially for the innermost layer of masonry – so the 150mm where condensation is most likely. This means that any driving precipitation should be mostly mitigated by this point, so any moisture added to this section of the wall would come from interstitial condensation. Both walls show their maximum reduction in this value during summer as the wall dries, gaining roughly the same amount as each other in winter. The assessment indicates that the wall using Procheck Adapt can lose more moisture, leading to a widening gap where the Procheck Adapt offers even higher performance as time goes on.

The water content in the insulation is also lower using the Procheck Adapt, as shown in graph 4. The results confirm that there would be less risk using Procheck Adapt on this wall compared to a regular vapour control layer. With the drive towards efficiency and reduction of emissions, buildings are becoming increasingly better insulated, more airtight, and more energy-efficient. So the management of moisture in building design and construction becomes critical. In doing so, experienced contractors are increasingly turning to Procheck Adapt as the intelligent solution to best practice approach to vapour control layers.

Graph 1

Graph 2

Graph 3

Graph 4