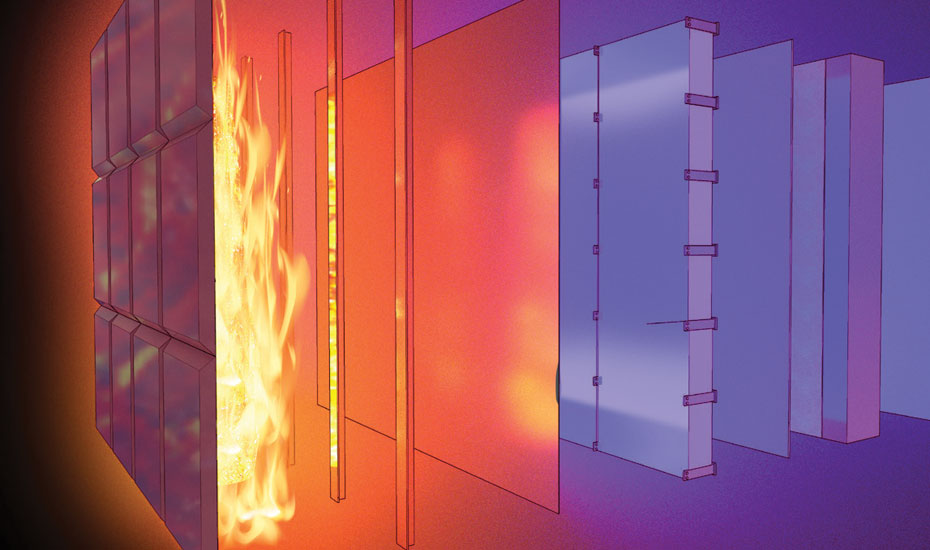

Meeting the challenge of delivering fit for purpose fire protection depends a variety of solutions tailored to individual project requirements, Ensuring the specification, installation and application are well matched is the key to a successful design.

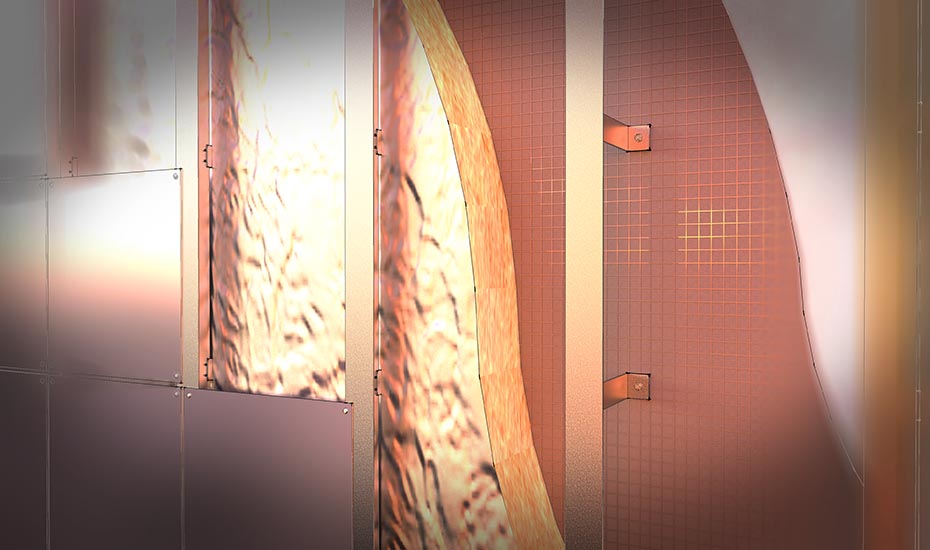

At Goldfinch Court, client Hills Partnership working with PCKO Architects undertook this project to replace and upgrade an existing residential facade comprising combustible ACM panels and rigid foam insulation.

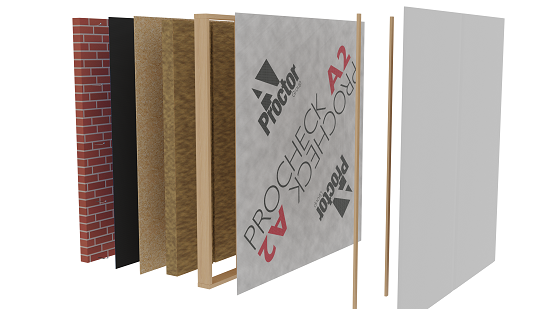

In addition to mineral fibre insulation and non-combustible cladding panels, the architects specified the Fireshield vapour permeable membrane from the A. Proctor Group Ltd.

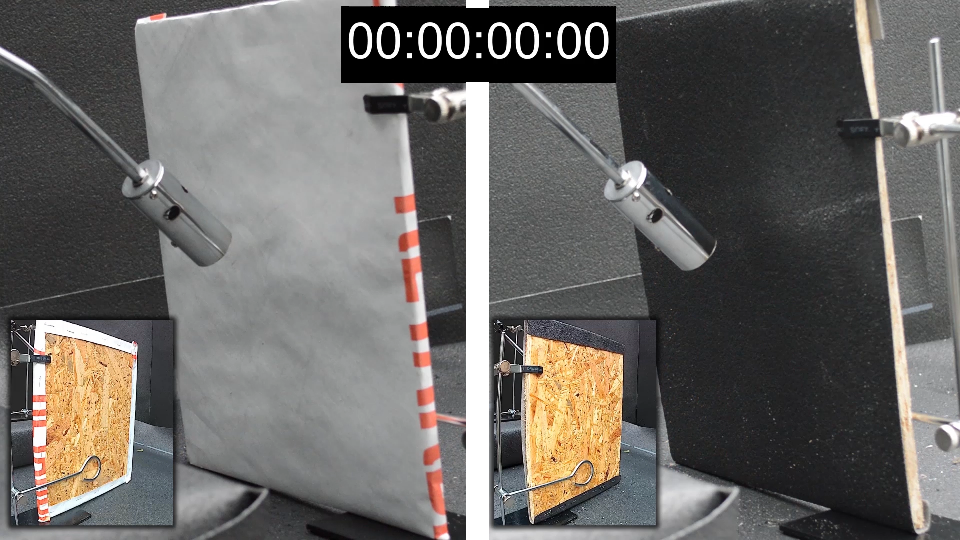

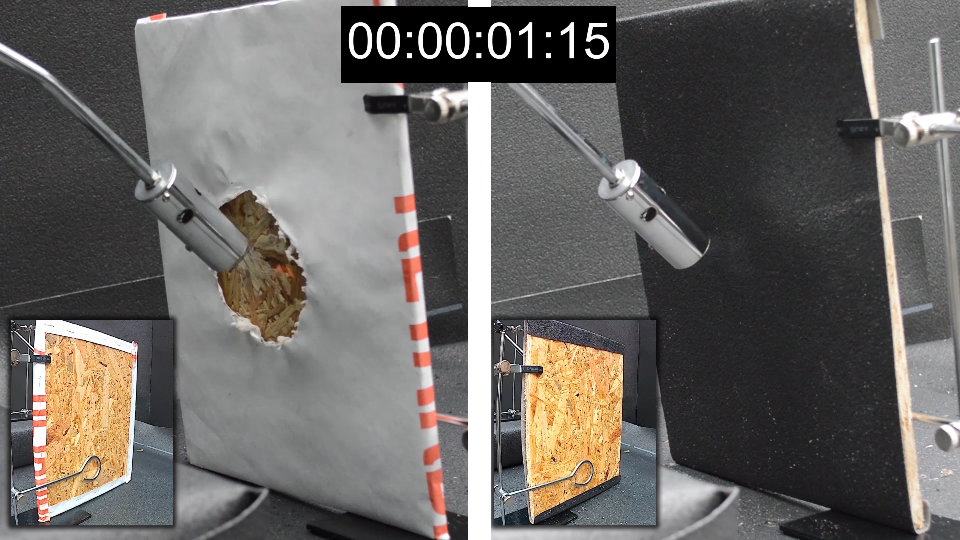

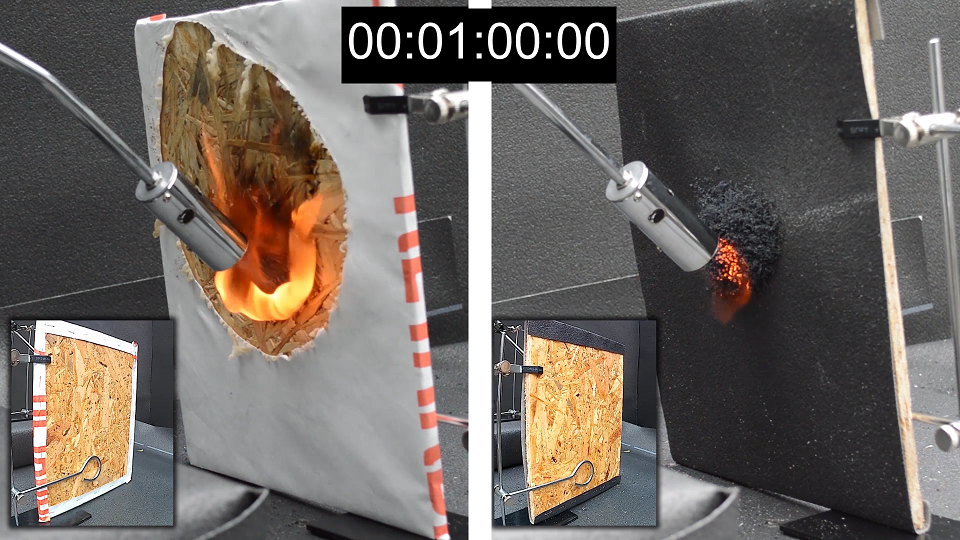

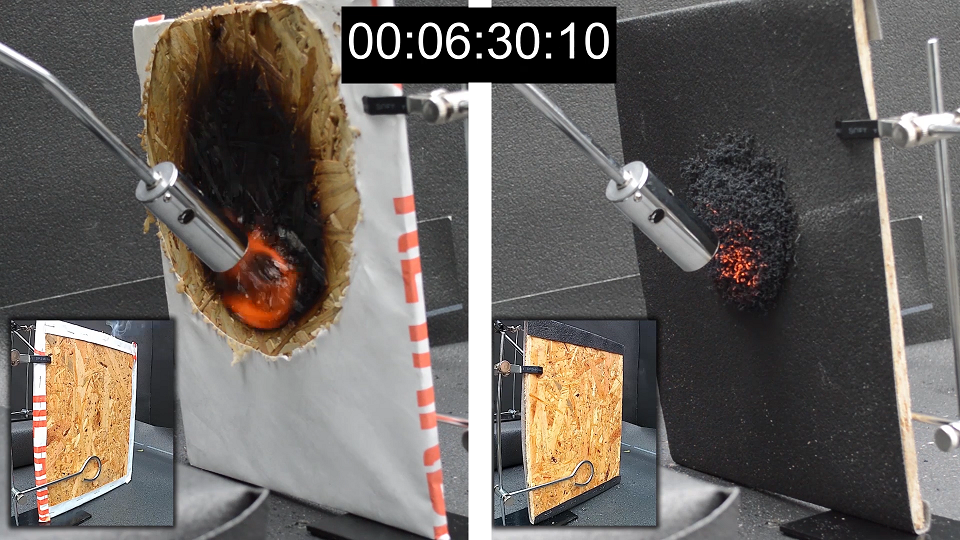

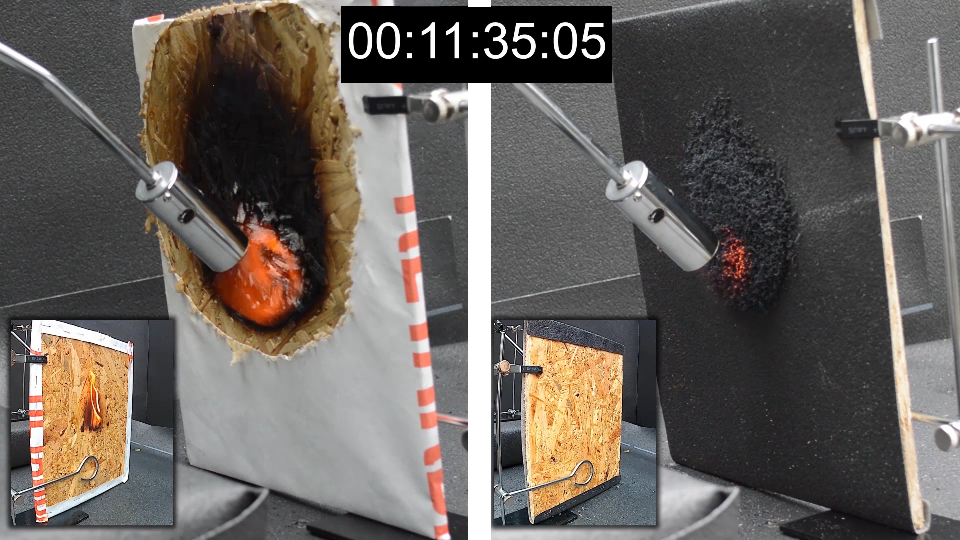

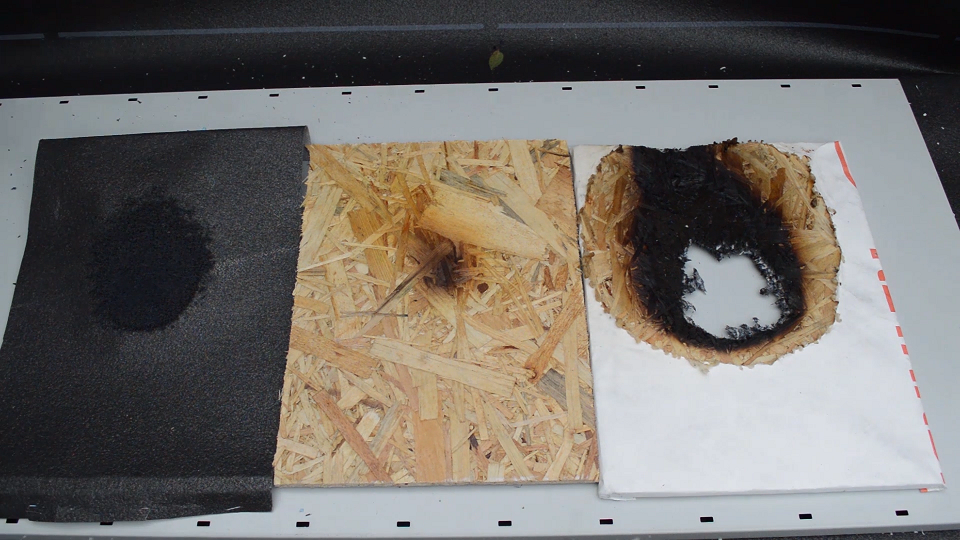

Correctly installed in accordance with the A. Proctor Groups guidance by contractors Facade Cladding Solutions, Fireshield has a unique intumescent composition that actively reacts to prevent fire taking hold. This coating extinguishes fire rather than just resisting it, and significantly reduces the formation of droplets and smoke.

Fireshield complies with BS5250, BS4016 and NHBC requirements for vapour permeable walling underlays, and also carries BBA certification and has LABC and LABSS registered details. It is installed and fixed to the substrate in the same manner as standard breather membranes using mechanical fixings. Applications include both commercial and residential buildings including apartments and student accommodation, as well as rainscreen cladding and applications over 18m high.