In addition, with specific reference to membranes, the Regulation provides an exemption and further clarification as stated below: “10.15 a. Membranes used as part of the external wall construction should achieve a minimum classification of European Class B-s3, d0.”

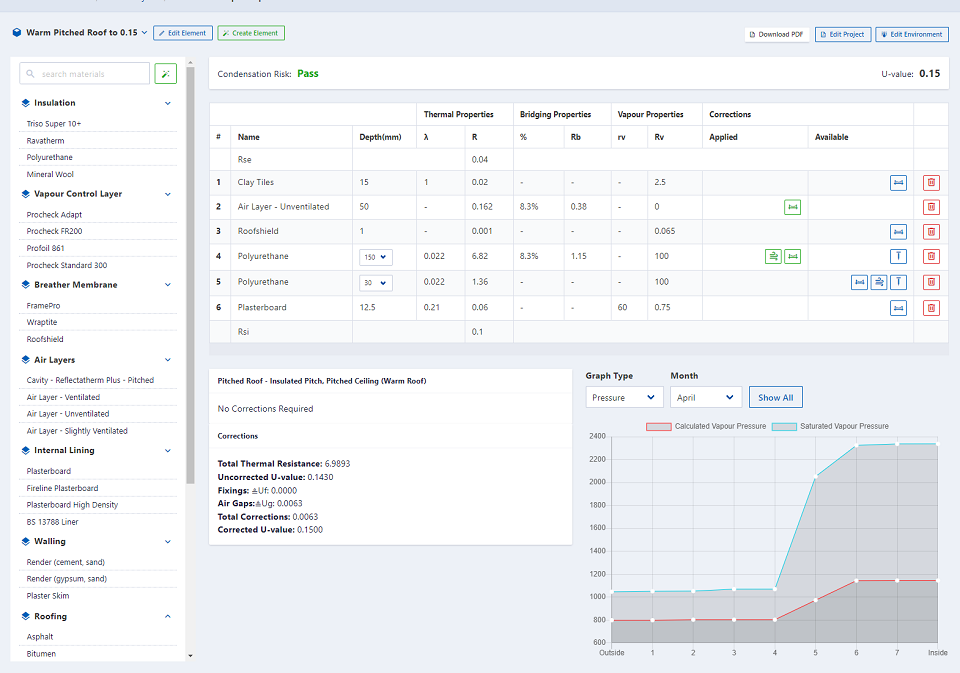

While quoting A2 ratings, some membrane products, especially vapour permeable membranes, do not breathe or comply with BS5250, meaning using these membranes in the UK climate could make the building unhealthy and result in a much greater risk of condensation issues and mould growth.

In developing its portfolio of advanced membranes, the A. Proctor Group has designed this in, backed up by independent testing observing the performance of the products as part of a holistic system rather than individually.

The latest examples include Procheck® FR200, a fire resistant vapour control layer used in roof and wall structures, and that provides a Reaction to Fire classification of B-s1, d0. Incorporating Procheck FR200 air and vapour tight membrane improves energy efficiency and reduces condensation risk.

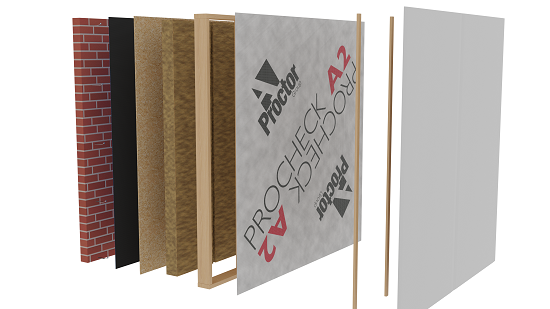

In addition, Procheck A2 is a laminated glass fibre and foil composition protected by a clear lacquer. This clear surface gives Procheck A2 a unique additional benefit of a low emissivity surface. When used with a service cavity, it can enhance the overall thermal performance of the construction and provide high fire performance with its A2-s1 d0 fire classification.

Now available, in combination with Procheck A2, is Procheck FR Tape, an aluminium faced, air and vapour tight tape designed for use with Procheck A2 and Procheck FR200 vapour control layers. When used in conjunction with Procheck A2, the Procheck FR Tape has a Reaction to Fire classification of Euroclass A2-s1, d0 for the system, or B, S1, d0 when used as a stand-alone product. This classification is unusual for tapes and is backed up by independent testing.

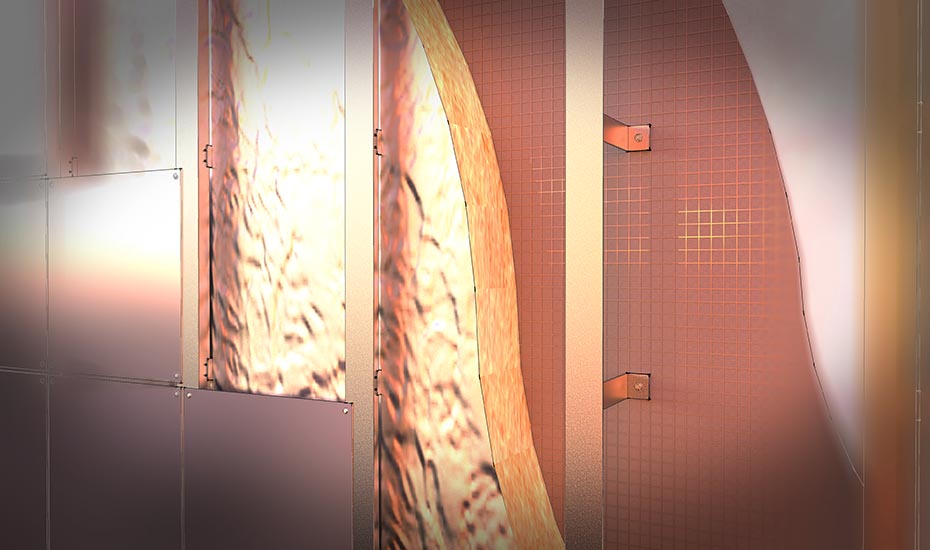

The increasing demand for independently certified vapour control layers to provide fire protection in compliance with the latest building regulations demands manufacturers understand how their products will be used within the total building system. The technical team at the A. Proctor Group is providing in-depth advice to the stakeholders involved in building design and construction on understanding this. Getting it right from the outset is crucial.