One of the most important amendments was the shift in classification of materials within ADB and the removal of references to BS 476-6&7 which previously classified products for Spread of Flame. The issue with the classification was that it only considered the reaction of the surface of the material being tested, and did not consider the combustibility of the whole product.

Standards & Building Regulations

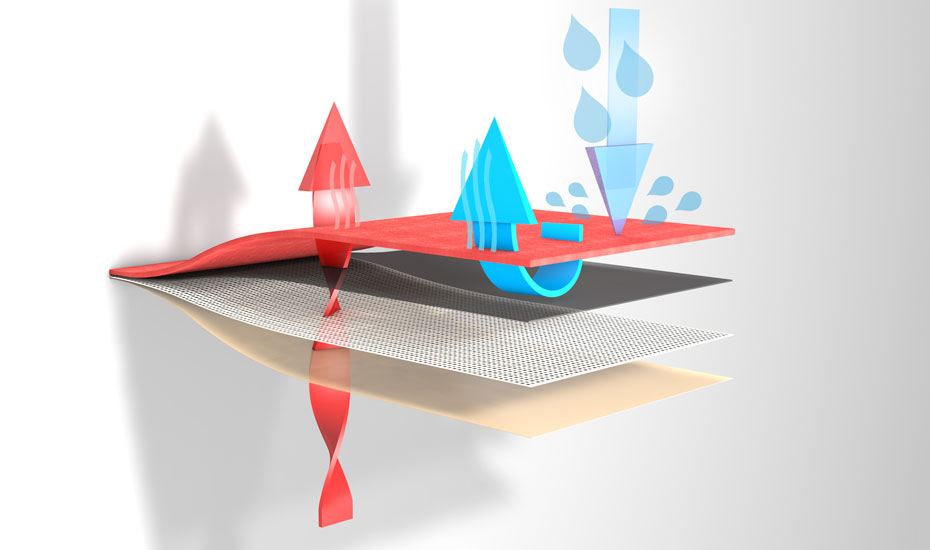

Due to the performance requirements of certain critical, flexible components within the external façade, such as breather membranes, the ability to achieve a non-combustible classification is inhibited by the nature of the materials from which they are made.

This was understood by the regulatory writers and therefore a list of exempt components has been included in Approved Document B to accommodate such products. Manufacturers are investing time and money into this area in order to provide an achievable fire classification without impeding the performance of the product.

In the amendment to Document B in November 2018 the required fire classification for breather membranes is stated to be:

“Membranes used as part of the external wall construction should achieve a minimum classification of European Class B-s3,d0”

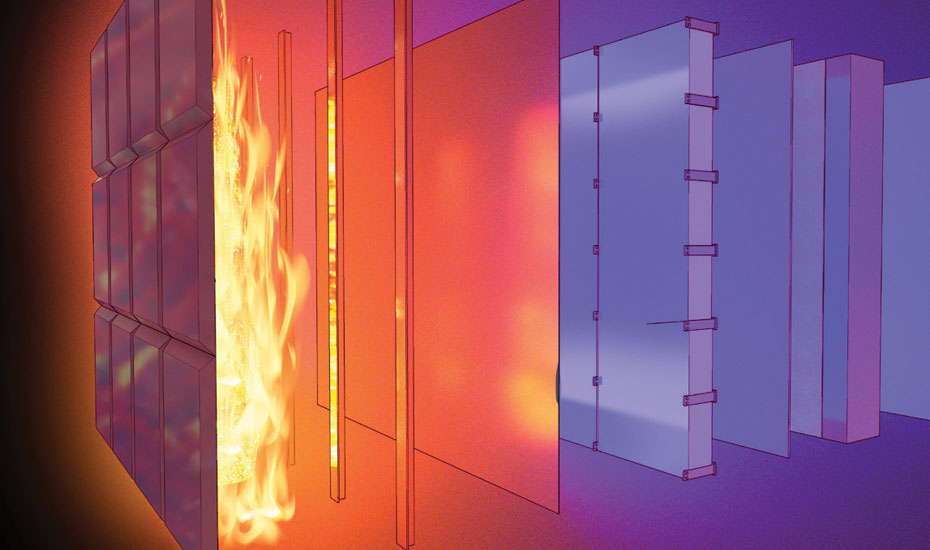

Traditionally breather membranes are mechanically fixed on low rise and taped on high rise. These membranes tend to shrink away from fire, however standard tests utilise a single focused burning flame which is widely challenged as the correct way to test a membrane for this application, and is not reflective of a real time scenario.

There is a clear benefit to using a self-adhesive membrane due to the material being fully adhered to the substrate. Therefore, there is no air gap behind the membrane and the substrate, meaning no flames can pass up the back of the membrane, as could happen with a loose mechanically fixed product.

Membranes & Fire Performance

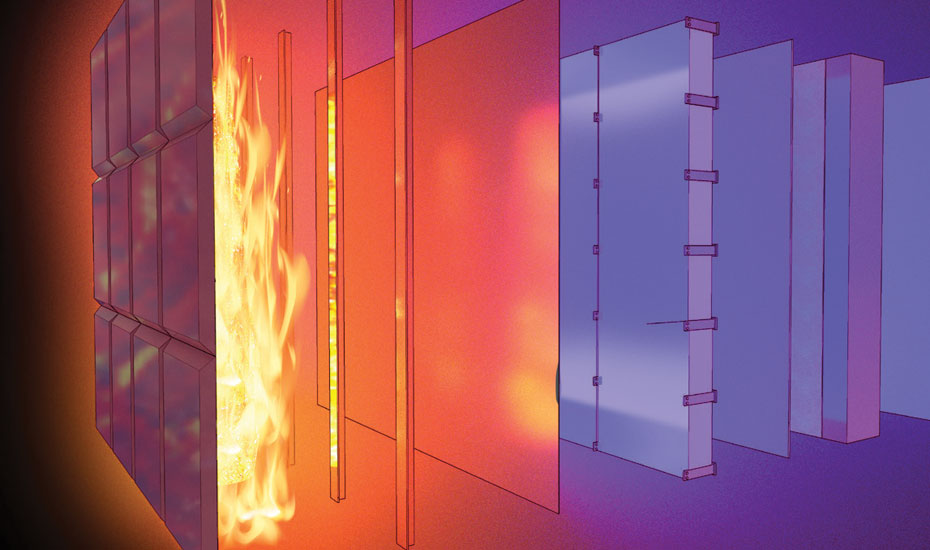

The increasing use of a self-adhered breathable membrane in high-rise development over A1 and A2 sheathing boards, has resulted in it being carefully considered in terms of performance in a fire context, which is of critical importance. Wraptite has therefore undergone classification to BS EN 13501-1 over a wide range of appropriate substrates

The results from these tests showed that Wraptite achieved a Class B-s1-d0, the highest classification that can be achieved from a polypropylene based membrane.

This performance allows designers to utilise the weather protection and air leakage performance benefits of Wraptite with confidence, even in the most demanding of applications where fire safety is critical.

However, if using a membrane in the cavity, either on lower rise buildings, or in high rise to add further protection to the system, products which actively resist fire, such as Fireshield are ideal.

Fireshield is a more rigid mechanically fastened product compared to lighter weight polypropylene membranes, in part due to the nature of its glass fibre backing. The weight and robustness of the product makes it less likely to billow away from the substructure, forming air gaps behind when installed correctly.

Fireshield’s specialist coating eliminates fire spread across the surface of the membrane and it is fixed using mechanical fixings. The intumescent facing actively resists the spread of flame by preventing it from taking hold due to the ‘foaming’ effect (expanding when it interacts with fire).

The A. Proctor Group provide a number of Breathable Membranes and Vapour Control Layers which have in depth testing to ensure confidence in the performance of the products in situ.

Fire Solutions In Practice - Goldfinch Court & Balfron Tower

Meeting the challenge of delivering fit for purpose fire protection depends a variety of solutions tailored to individual project requirements, Ensuring the specification, installation and application are well matched is the key to a successful design.

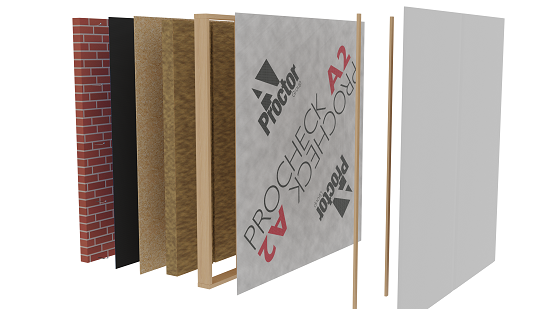

At Goldfinch Court, client Hills Partnership working with PCKO Architects undertook this project to replace and upgrade an existing residential facade comprising combustible ACM panels and rigid foam insulation.

In addition to mineral fibre insulation and non-combustible cladding panels, the architects specified the Fireshield vapour permeable membrane from the A. Proctor Group Ltd.

Correctly installed in accordance with the A. Proctor Groups guidance by contractors Facade Cladding Solutions, Fireshield has a unique intumescent composition that actively reacts to prevent fire taking hold. This unique coating extinguishes fire rather than just resisting it, and significantly reduces the formation of droplets and smoke.

Fireshield complies with BS5250, BS4016 and NHBC requirements for vapour permeable walling underlays, and also carries BBA certification and has LABC and LABSS registered details. It is installed and fixed to the substrate in the same manner as standard breather membranes using mechanical fixings. Applications include both commercial and residential buildings including apartments and student accommodation, as well as rainscreen cladding and applications over 18m high.

Fire Solutions In Practice - The Balfron Tower

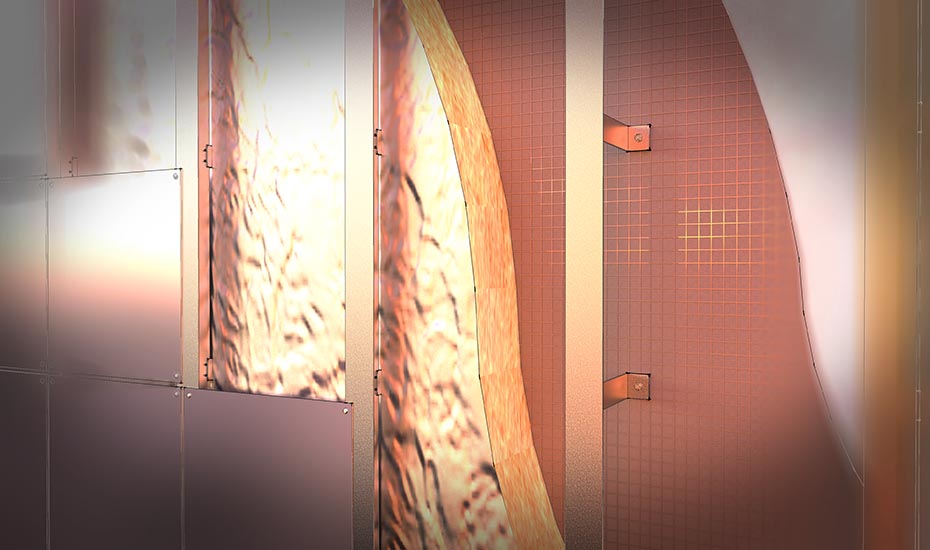

Another project, The Balfron Tower (left image) involved the upgrading and refurbishment of a Grade II* listed 1960’s building in the London Borough of Tower Hamlets, originally designed by the renowned architect Ernö Goldfinger.

The existing wall construction meant that space for traditional insulation was limited in some instances. Spacetherm A2 was capable of achieving the BRE’s surface condensation analysis target temperatures of 16°C, with minimum loss of space.

The concrete walls around the stairways in each apartment were particularly space critical and identified as a weak point for cold bridging.

The original specification would have required an additional insulated wall lining of 145mm, whilst using Spacetherm A2 the required high-performance insulation was achieved in less than 60mm.