Aerogel is the world’s lightest solid material; in its raw form its composition is over 90% air.

A highly effective insulator, it has the lowest thermal conductivity of any solid known to man, and has broken over 15 world records. Aerogel was first created by scientist Samuel Stephens Kistler in 1931, the result of a bet with a colleague over who could replace the liquid in “jellies” with gas without causing shrinkage.

It has been used in thousands of applications since its invention, for example NASA – National Aeronautics and Space Administration discovered that in its raw form, aerogel was capable of collecting stardust from space.

The history of aerogel is pretty fascinating, but what’s amazing is how it is used in everyday life to solve real problems for people everywhere.

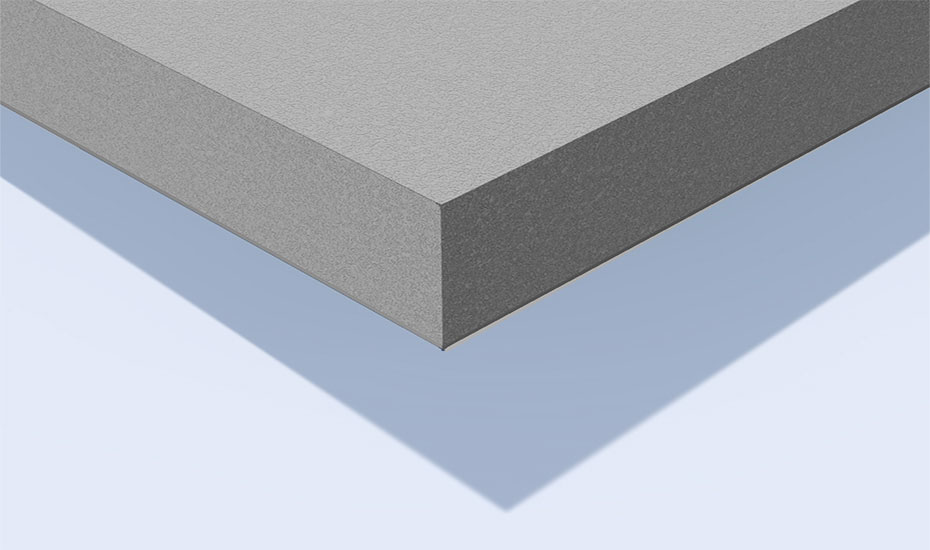

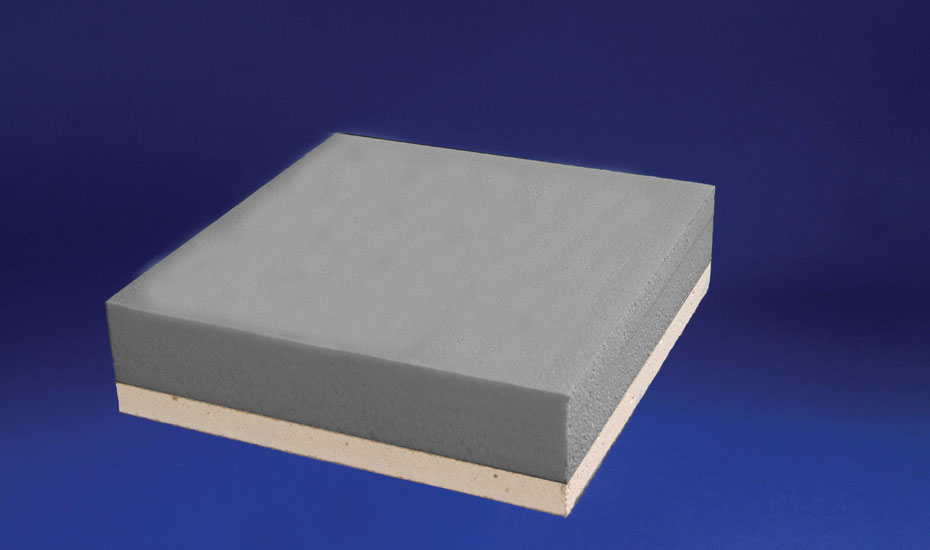

The name ‘aerogel can be misleading however, as it is in fact, a dry, rigid solid. The name stems from the fact that aerogel is derived from a wet gel, the liquid component having been replaced by a gas in most cases.

The result of this process is a solid with extremely low density, and crucially, very low thermal conductivity. The conductive insulation properties of aerogel are unrivalled.

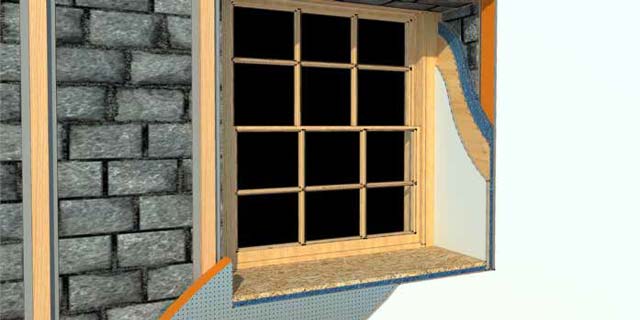

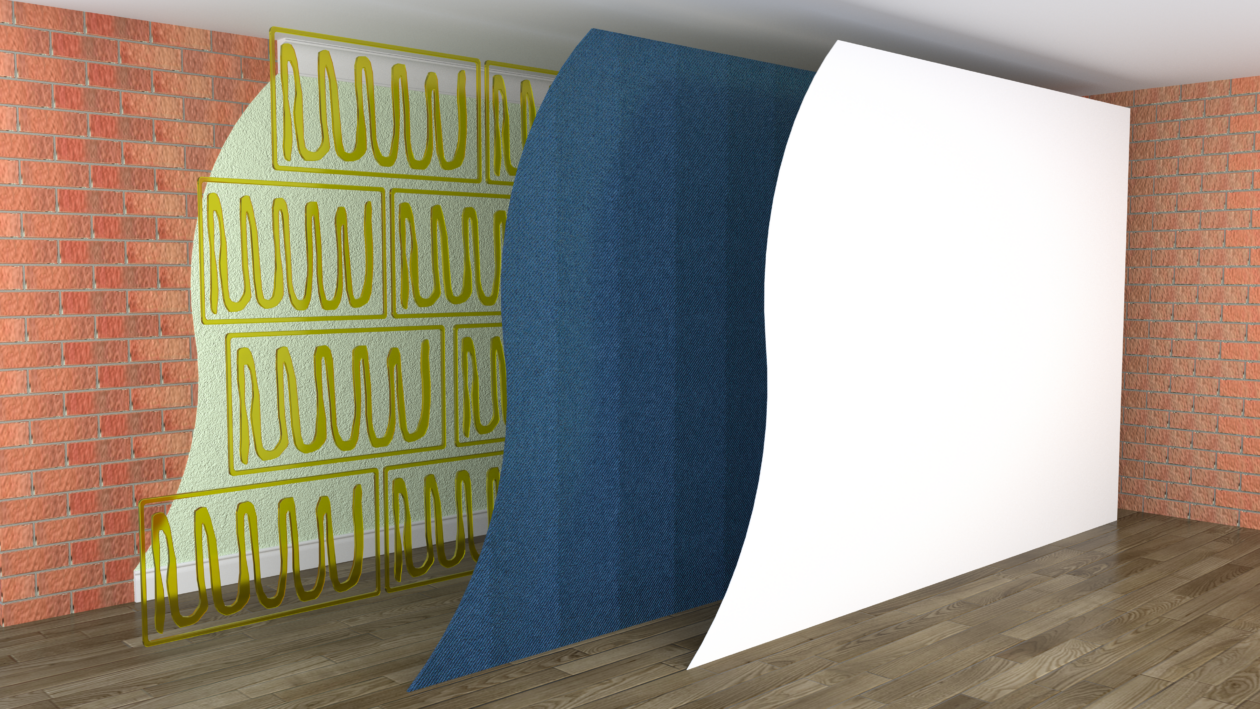

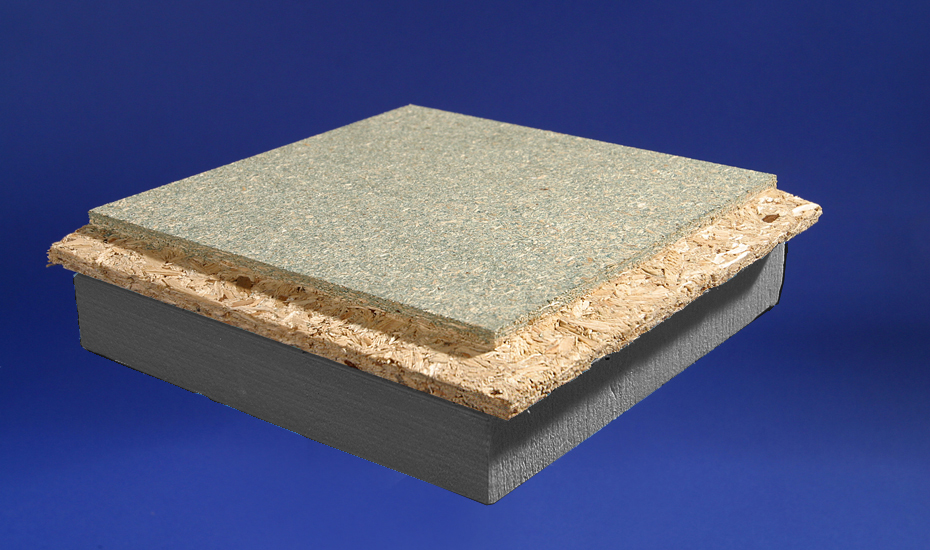

The A. Proctor Group Ltd. Group’s Spacetherm® Aerogel combines a silica aerogel with fibres to produce a flexible blanket solution.

We have a range of Spacetherm® Solutions for retrofit and new builds.