Underlays are then split into two main categories, High Resistance, or HR underlays and Low Resistance, or LR underlays. HR underlays are equivalents to the traditional 1F felts, and will require full ventilation below them. LR Underlays must have a vapour resistance below Sd 0.05m (0.25MNS/g).

There are other key performance criteria that are required, ie water resistance. Walling underlays require a minimum Water Hold Out Classification of W2 whereas roof underlays require to be W1 which is more onerous to achieve. A further distinction is the air permeability or airtightness of the underlay, both have benefits depending on the design.

What are the benefits of air permeability in a roof?

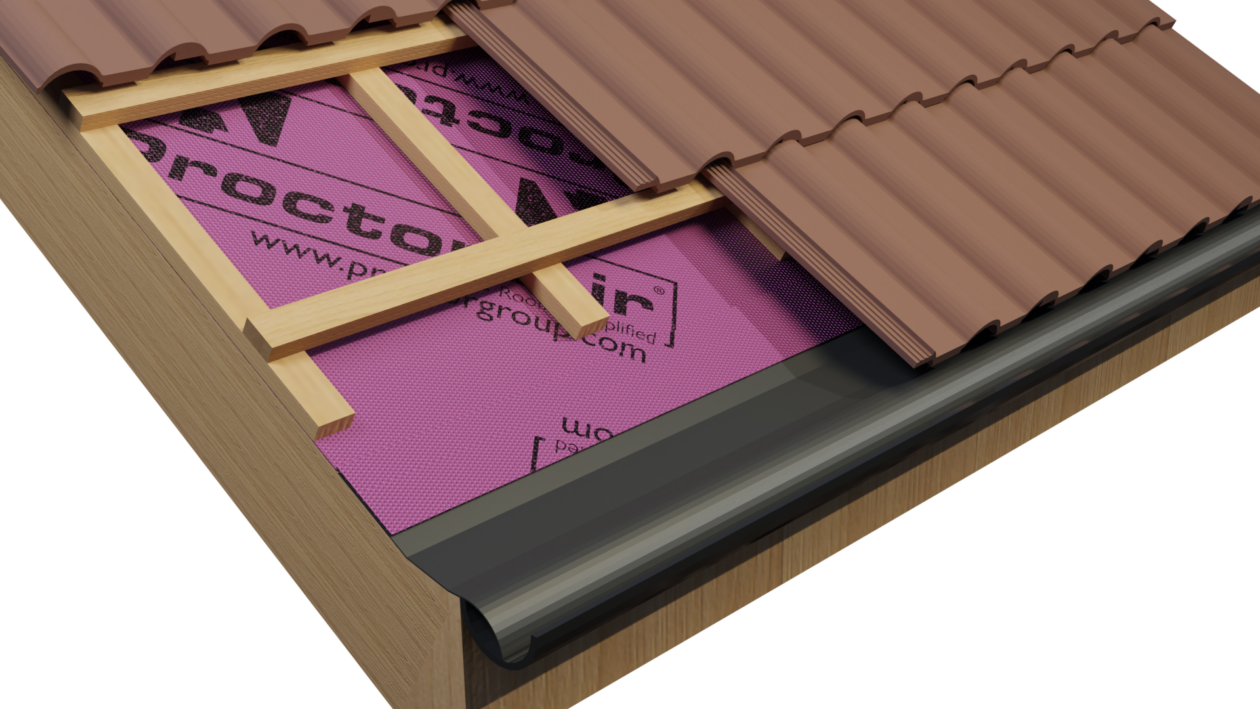

APLR underlays (air permeable low resistance) allow air to circulate through the layers of the membrane, in combination with having low vapour resistance. Airtight underlays, the most common type in the UK, allow vapour to disperse via diffusion through the layers, having been made with a microporous film layer in the middle of the underlay. Air permeable underlays allow vapour dispersal by two mechanisms, diffusion as well as in the air passing through the underlay. This is down to the unique meltblown core.

Assessments carried out by BRE and Glasgow Caledonian University have shown that air movement through the underlay increases the vapour removal from the roof and can be similar to that achieved by both eaves and ridge ventilation. The ability to remove ventilation from the roof can be a huge benefit with the increased need for insulation, and the difficulty in maintaining ventilation pathways, stopping cold bridging, as well as making complex and historic roofs easier to detail and more aesthetically pleasing.

If you are building a project that is NHBC registered the use of an air permeable underlay can also mitigate the requirement for high level ventilation in cold roof constructions, this ventilation is required where an airtight underlay is used.

Proctor Air falls into the category of APLR’s and therefore can be used without vents. For project specific advice our Technical Team are on hand to review your designs.

How does Proctor Air perform in extremes of weather?

Developing Proctor Air allowed us to look at what the membrane needed to do which therefore meant we could enhance attributes that are important for the UK climate, ie wind, rain and UV exposure.

Underlays are NOT designed to be primary weatherproofing layers, and as per BS5534:2014, Code of practice for slating and tiling, they should not be relied on as a temporary protection during adverse weather, such as storms and freeze/thaw cycles. In these conditions, especially re-roofs, the use of a protection layer, ie tarpaulin, should be considered. UV exposure guidance relates to the effects of sunlight on the membrane and does not mean that the membrane will remain water resistant for this length of time. Proctor Air contains hydrophobic additives in all three layers to help improve water resistance.

Wind uplift resistance is also excellent with Proctor Air. At 345mm batten centres it can be used in Zones 1-4 in the UK and with centres at 250mm, or laps sealed with Wraptite Tape, it can be used in in Zones 1-5.

Does Proctor Air have a warranty?

Yes, it does. We are delighted to be able to offer a 15-year warranty on the Proctor Air, details of this are in our literature and installation guide and is available to all.