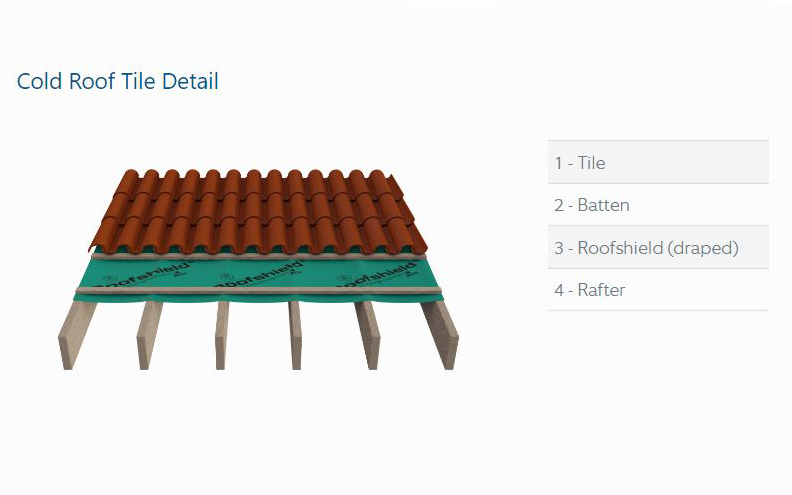

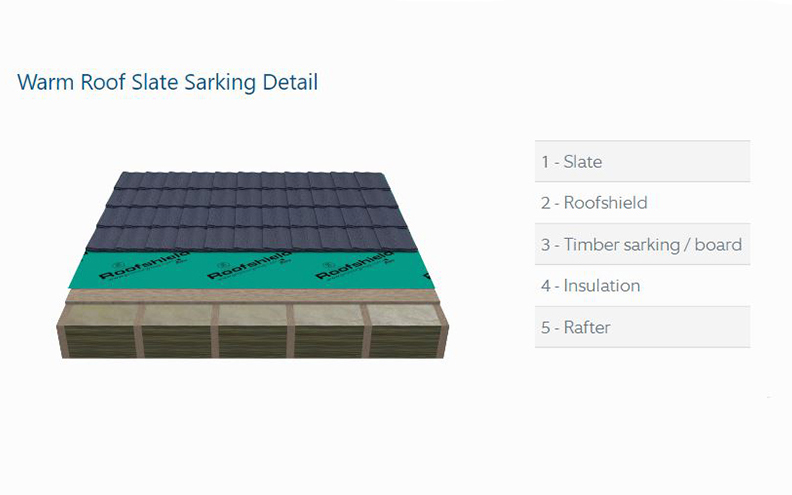

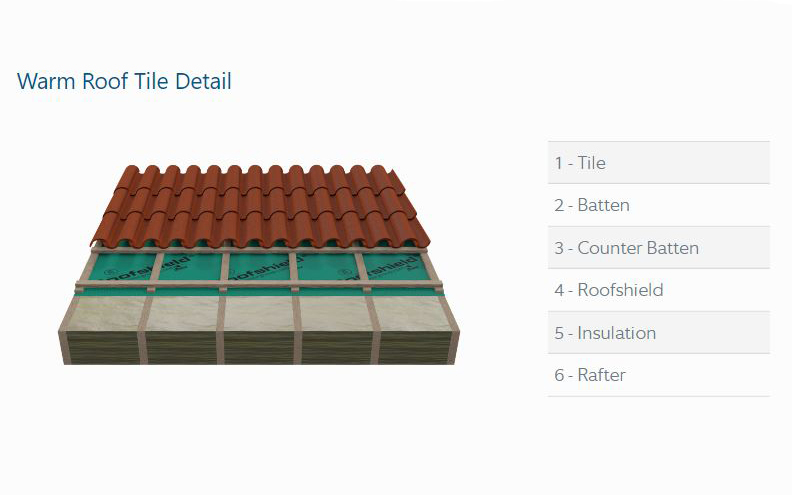

All activities within a building, from initial construction and wet trades, to cooking and washing, generate substantial amounts of water vapour, which must be managed successfully to ensure the longevity of the building fabric and a healthy indoor environment. The vapour permeable structure used in these membranes allow this to be achieved without compromising temporary weather protection during construction, or requiring complex and expensive passive or active ventilation systems and accessories.

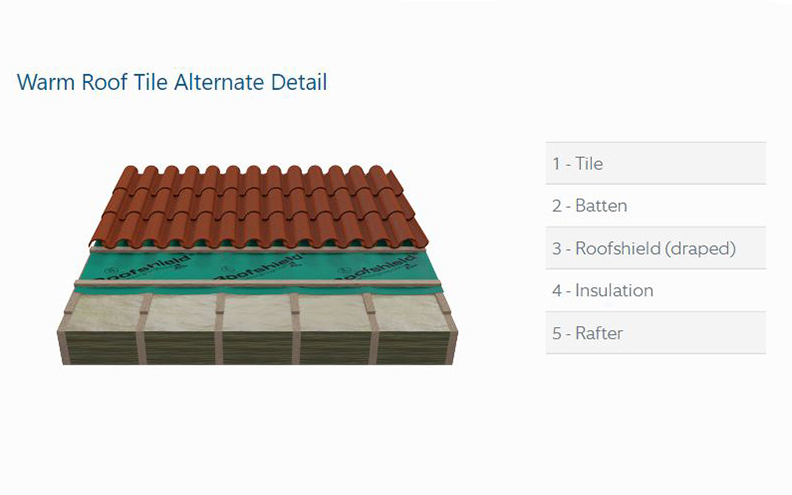

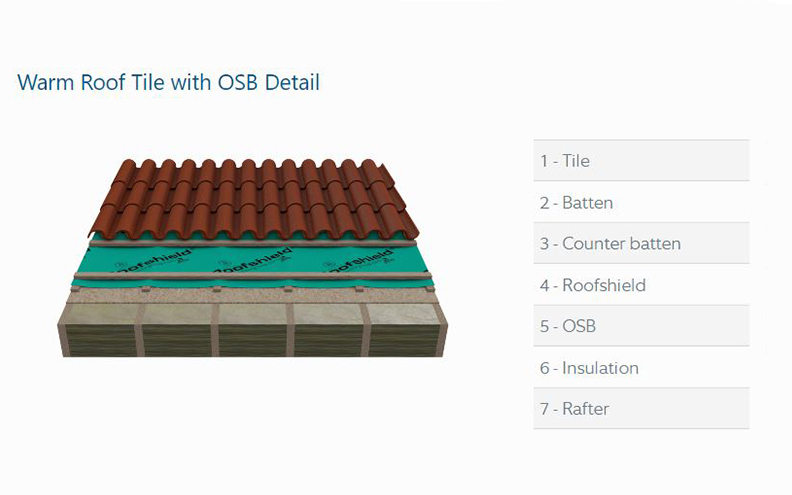

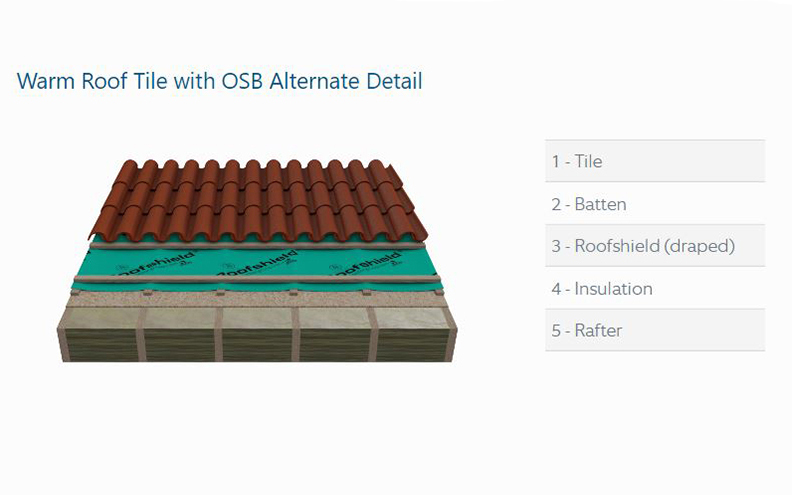

While such systems may once have seemed somewhat alien to the industry, non-ventilated roof constructions, with their speed, efficiency and lower cost are fast becoming the norm. The once radical building physics behind them now well understood and widely accepted across all sectors of the industry.

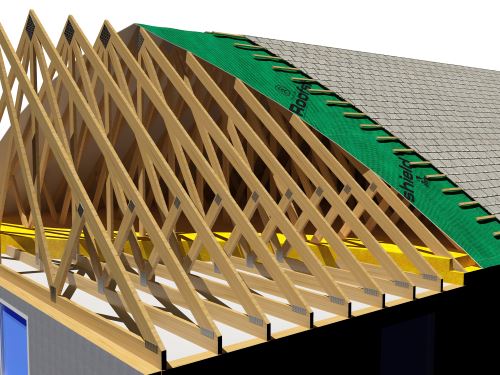

Roofshield is a vapour- and air-permeable underlay (VPU) for pitched roof applications. First launched in 1996, and with an unchanged specification since, it’s unique blend of physical properties has allowed it to consistently outperform not only competing vapour permeable underlays, but also traditionally ventilated roofs

While the majority of VPUs in use today utilise an airtight VP film layer to achieve their performance, Roofshield’s patented SMS (Spunbond Meltblown Spunbond) structure allows high levels of airflow in addition to the transport of moisture vapour, making the formation of condensation virtually impossible. It was this outstanding air-permeability powered performance in BRE trials that led to the granting of one of the first BBA certificates for non-vented cold roofs in 1999, and which today allows the NHBC to accept its use without high level vents, a position further reinforced by NFRC Technical Bulletin 6 in 2012. Independent studies of the effect of air permeability have confirmed that lofts using Roofshield have a more consistent air flow through the roof than those found in traditionally ventilated lofts, according to BS5250, so whatever side of the vents/no vents debate you sit on, Roofshield has it covered.

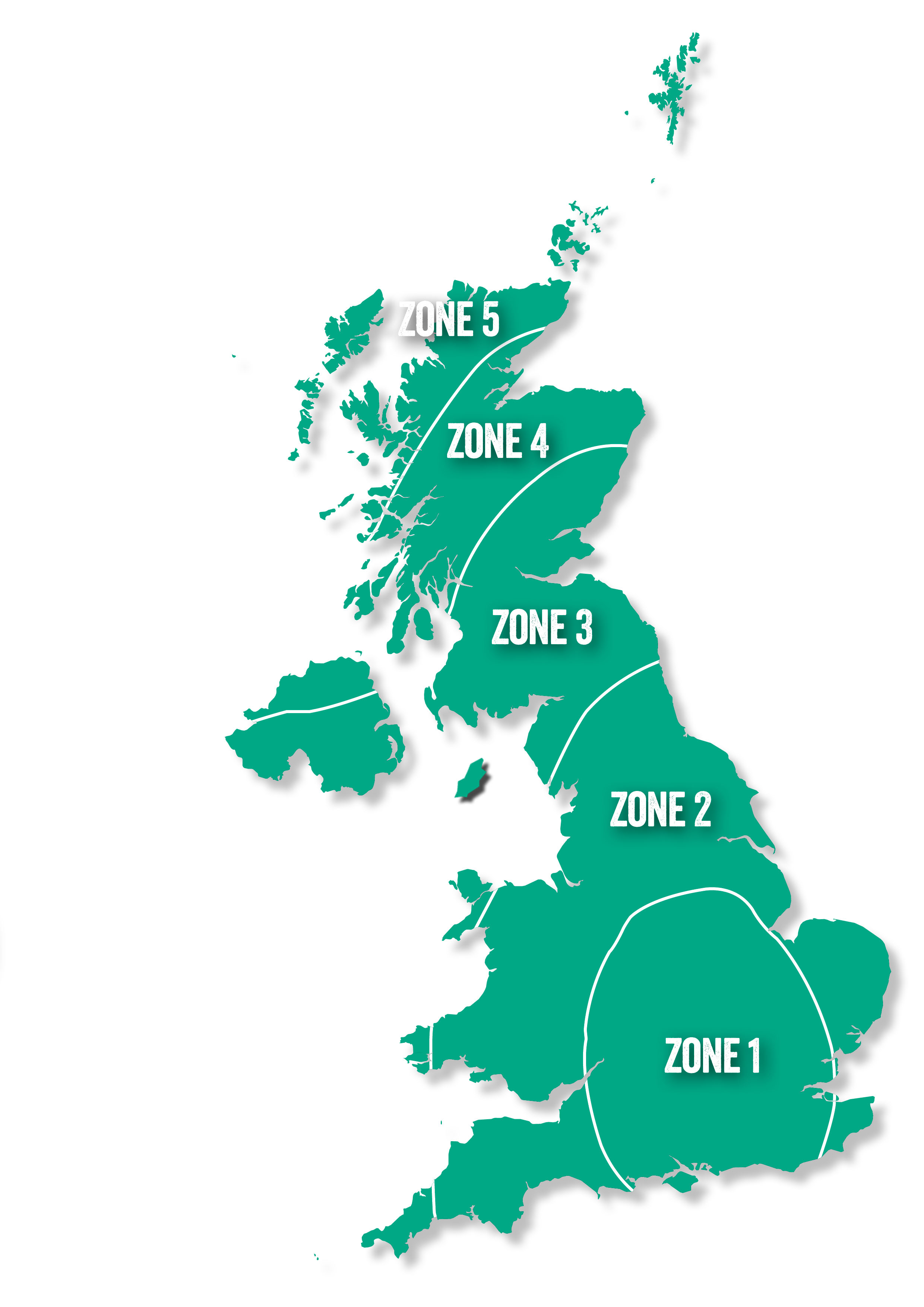

Developed and manufactured in Scotland, Roofshield has been widely used in some of the harshest climates on earth, from northern Canada to the Antarctic, and it’s superb resistance to wind loadings allow it to be used without restrictions on batten spacing in any UK exposure conditions, giving specifiers the flexibility to choose whatever configuration of outer roofcovering meets their requirements. Its heavyweight 185gsm three-layer structure is also fully hydrophobic, giving a Class W1 rating under the latest EN13859-1 specifications, and at Euroclass D offers the highest available fire rating in its class.

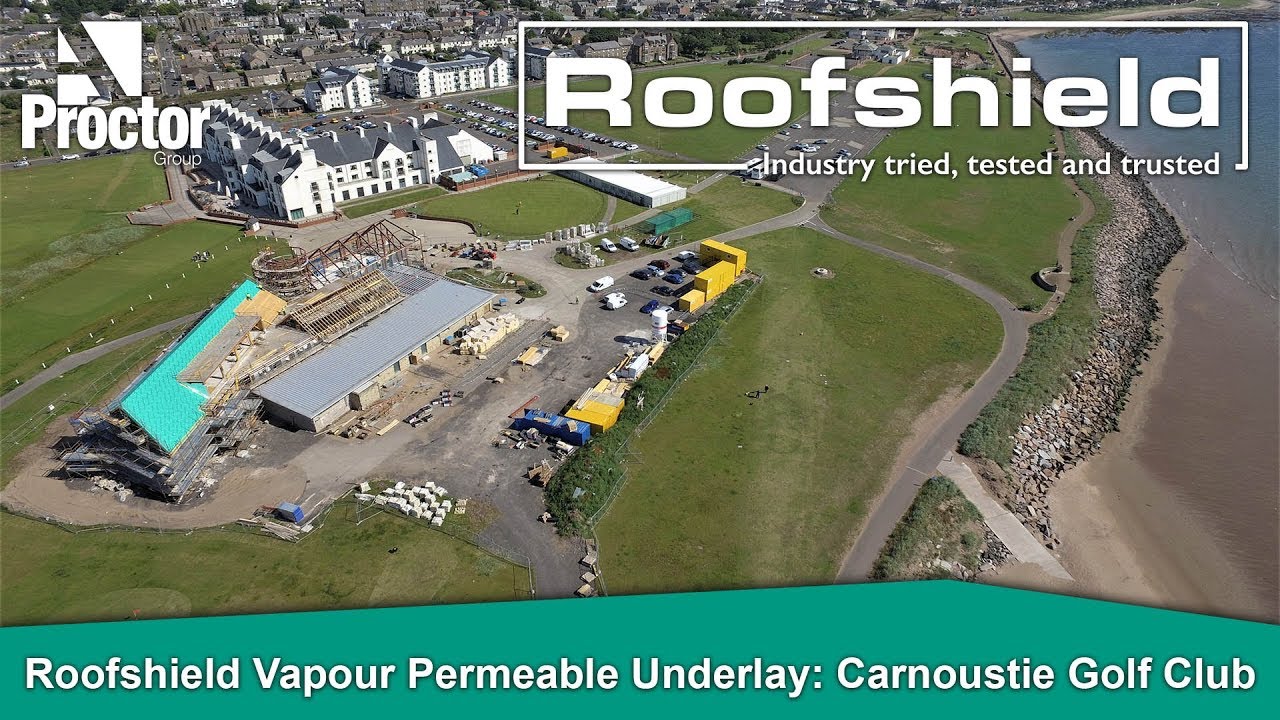

Over the last 20 years, we have undertaken projects from domestic housing to the refurbishment of historic castles. The performance and design flexibility of Roofshield provides a winning combination time and again. It has become recognised as one of the most dependable solutions for specifiers and contractors available globally