Wraptite airtight membrane has been selected by the Zero Bills Home Company and RIBA award winning development pioneers ZEDfactory in their latest innovative solution to deliver zero carbon housing. The Zero Bills Home has been built at the world-renowned BRE Innovation Park in Watford.

The Zero Bills Home concept, is said to offer a fresh approach to the significant challenges faced by the housing market, and offers a pre designed, engineered, and costed housing solution with an option for customisation. The intelligent design seeks to minimise energy requirements, make home energy bills a thing of the past and offer a truly sustainable solution to the demand for more housing.

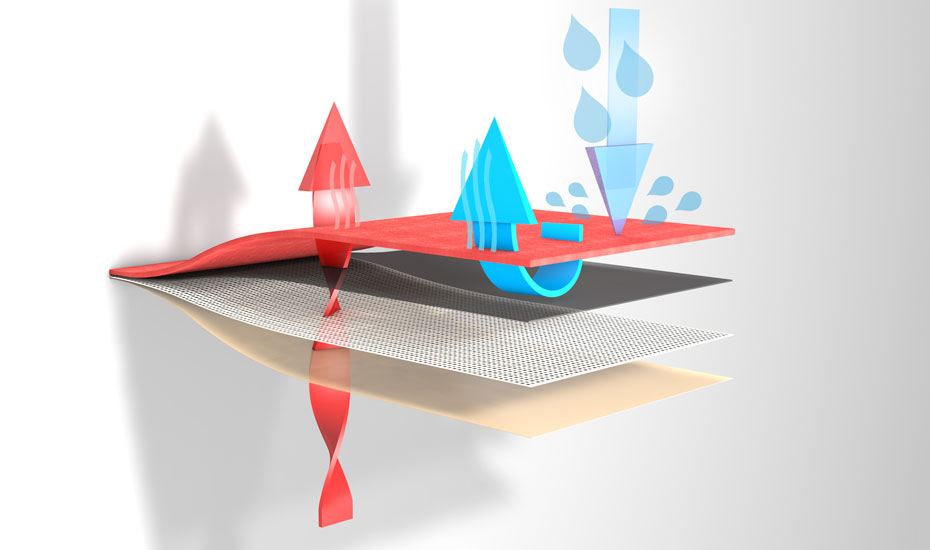

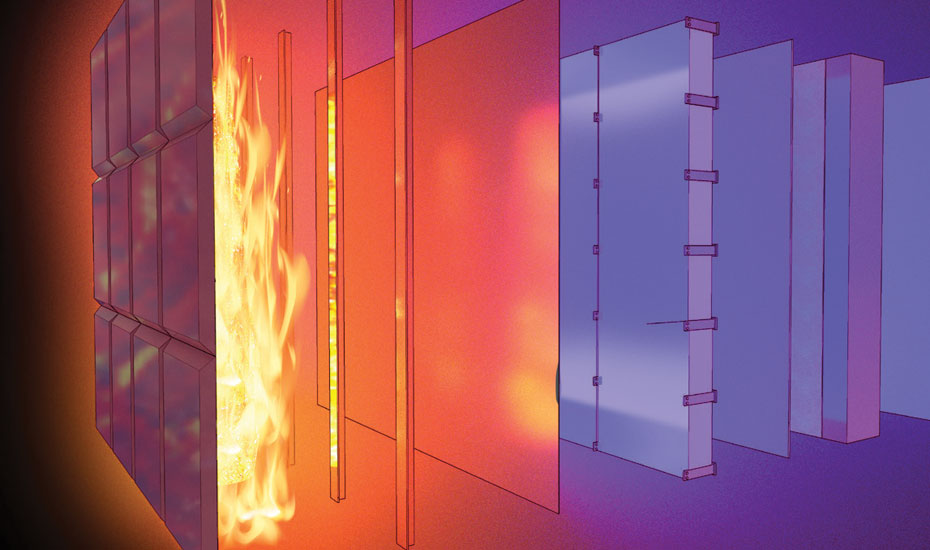

Wraptite, the only self-adhering vapour permeable air barrier certified by the BBA, was installed as part of the OSB panel construction of the home. The use of Wraptite in the construction makes a significant contribution to a building’s thermal performance by preventing lateral air movement. It also provides high vapour permeability in a continuously sealed, self-adhered, airtight membrane.

Unlike internal air barriers, which can be complex and costly to install due to the need to accommodate building services such as electrical, lighting, heating and drainage systems, Wraptite was applied externally, quickly and easily to the OSB boards in continuous pieces. The membrane fully bonds to virtually any substrate, requiring no mechanical attachment to suppress air leakage around junctions or penetrations. On the Zero Bills Home project the results for airtightness were exemplary, achieving on the first test 1.3 ac/h at 50 pascals.

Another key benefit of the system is that Wraptite’s high vapour permeability allows damp sheathing to dry quickly and moisture vapour to escape. This ensures good indoor air quality and reduces the likelihood of mould, mildew, condensation, timber distortion and metal corrosion.