Approved Document B: Amendment November 2018

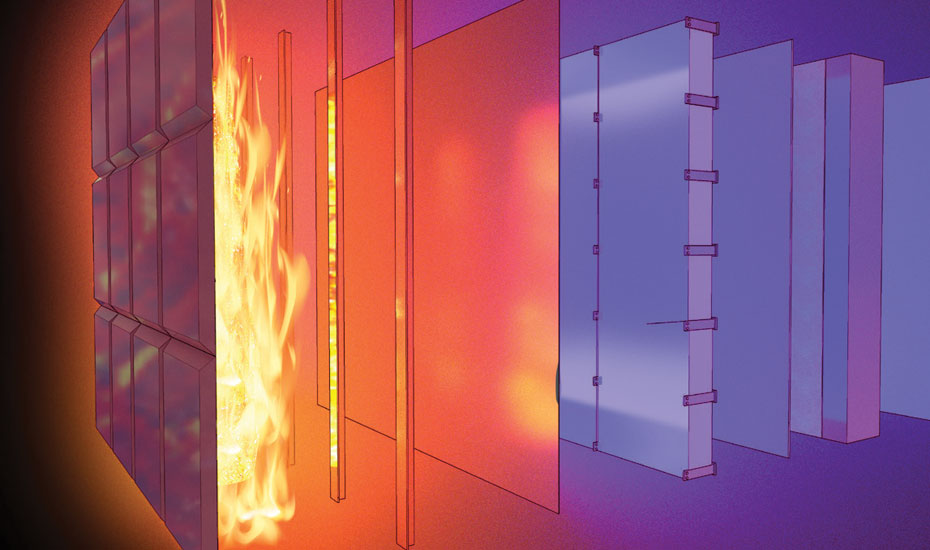

Following the Independent Review of Building Regulations and Fire Safety and subsequent Interim Report by Dame Judith Hackitt, the Government introduced an amendment to the Approved Document B: Fire safety, which has a significant impact on the design and construction of buildings above 18 metres. Published in November 2018, the new regulations came into force on 21 December 2018. Guidance on how external walls can meet the Building Regulations requirement for resisting fire spread is set out in Approved Document B.

The use of membranes within external wall construction

It is important to note that with specific reference to membranes the Regulation provides a critical exemption and further clarification is found within Regulation 7, as stated below:12.14 Particular attention is drawn to the following points.a. Membranes used as part of the external wall construction should achieve a minimum classification of European Class B-s3, d0.

Breather Membranes – vapour permeable

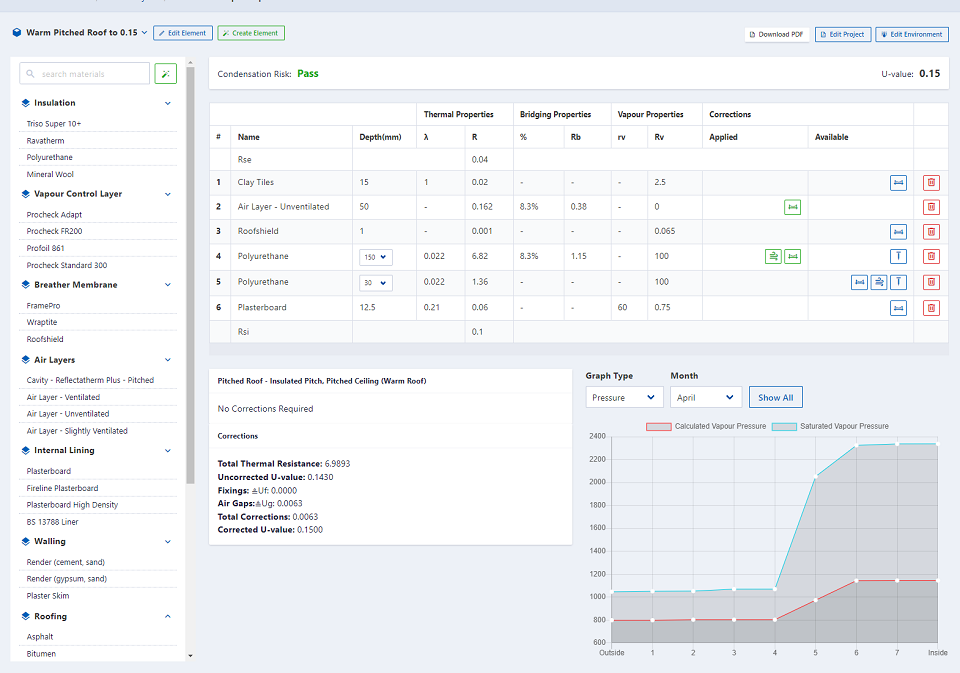

In selecting a membrane it is important that performance is not compromised and that compliance meets the requirements of both Approved Document B: Fire Safety and BS5250 the Code of Practice for Condensation Control.

It is crucial that specifiers understand that some European membrane products whilst quoting A2 ratings do not breathe sufficiently to comply with BS5250, meaning the use of these membranes in the UK climate could make the building unhealthy and result in a much greater risk of condensation issues and mould growth.