Network Rail Testimonial

“In the 3 years that Network Rail has been supplied insulated products from the Proctor Group; I have been impressed at their ability to grasp a new market sector. Whilst the Proctor Group is not a multi-national organisation; this is actually a strength as they react more quickly to the need of the customer. During 2012/13 Network Rail delivered a project to improve the points heating; with 2,250 point ends being fitted with heat retainers. 80% of these points were installed with the Proctor product.”

Tony Jackson, Network Rail

Rail Solutions Contact

If you have any questions, would like to place an order, or would like further product information, please contact our distribution partners SAN.

The Tracktherm® Insulating Strip

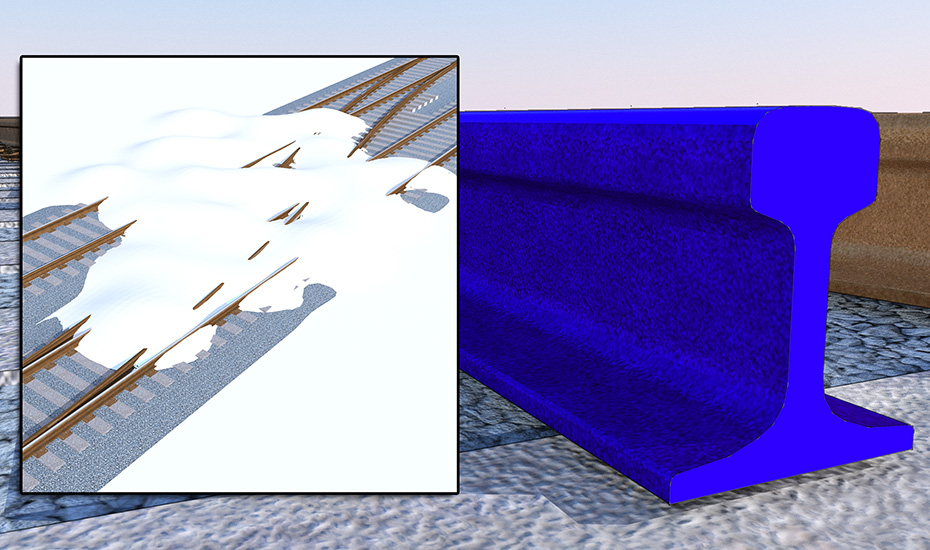

Railway Points with no heating

Railway points with no heating can be difficult to keep operational under challenging winter weather conditions, leading to train delays and cancellations.

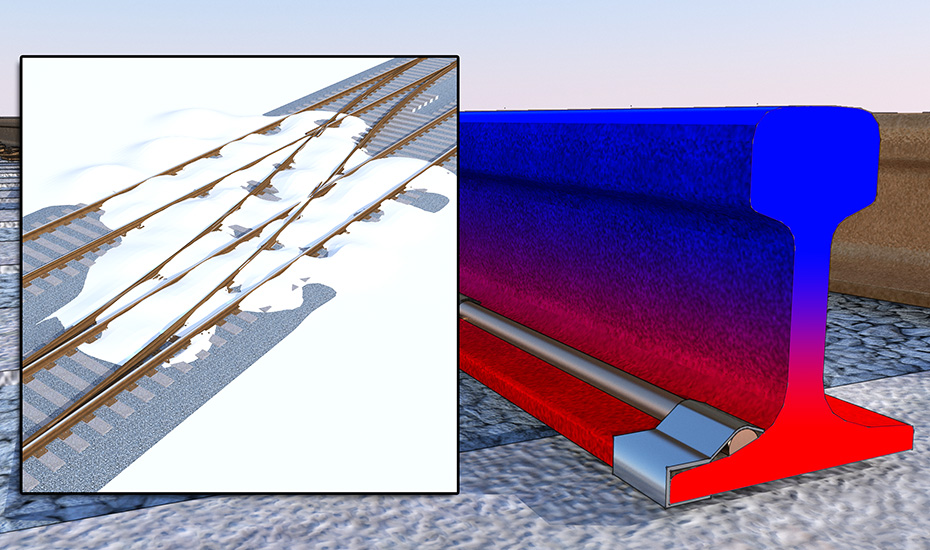

Railway points with uninsulated heating strip

Railway points with an uninsulated heating strip are better at keeping the points operational, however much of the heat generated is lost to the open air.

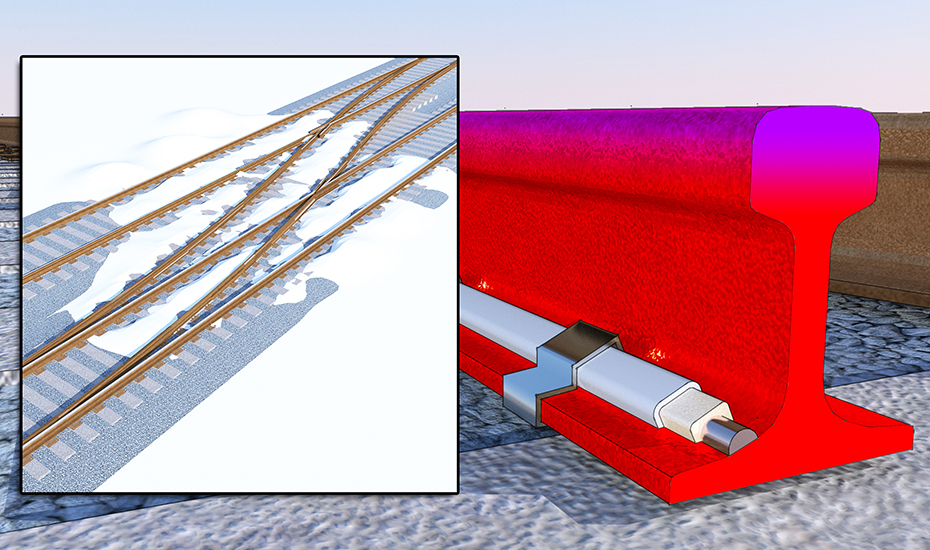

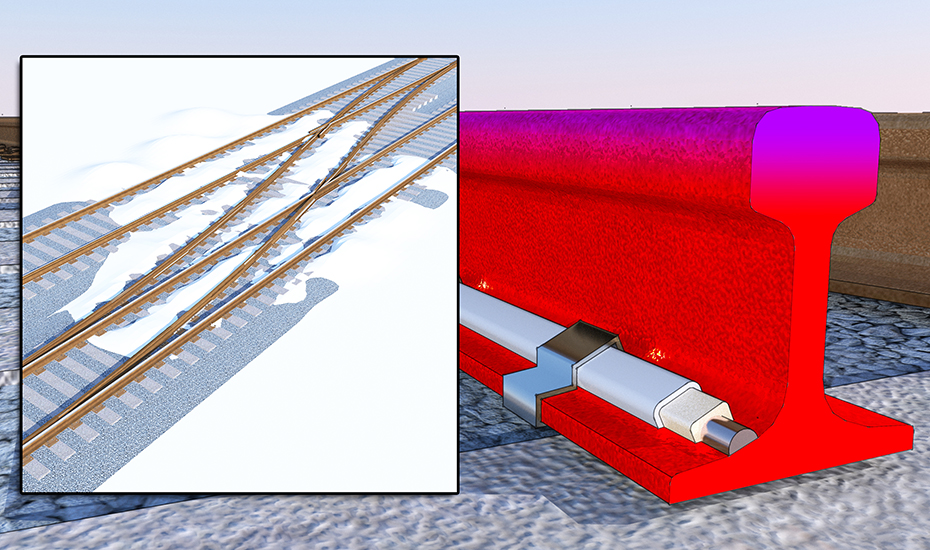

Railway points with Tracktherm insulated heating strip

Heating elements covered with Tracktherm® insulating strips offer the best performance, directing the generated heat towards the rail.

Keeping things on track in Britain’s unpredictable climate

For years Britain’s economic prosperity has depended on a strong and efficient rail network. When rail services are disrupted and cannot meet people’s needs for routing or frequency, business and jobs suffer. Maintaining rail links with airports and ports is essential for travel, tourism and the transportation of goods.

Britain’s unpredictable climate, the effects of weather extremes, and severe winter conditions can prove a real challenge for rail infrastructure managers and engineers in keeping the network open and running. Increasingly becoming recognised for the benefits they provide in improved performance and minimising winter delays, Tracktherm® Point Heating Insulating Strips from the A. Proctor Group are keeping things on track.

Preventing frozen tracks and minimising delays

During winter and sudden cold spells, frozen tracks result in speed restrictions and potential termination of service. Modern points heaters use electric heating elements rated at 200-400W/m, clipped to the rails to heat a set of points, to prevent ice forming and keep the switch blades moving. However, traditional heating elements are not insulated and therefore a lot of the heat is lost to the atmosphere, making points heaters inefficient, and such systems can take up to 2 hours to reach operating temperature.

In conjunction with Network Rail and its contractors, the A. Proctor Group developed Tracktherm insulating strips. Tracktherm offers improved performance by directing the heat specifically towards and into the rail, reducing the energy consumed in heating the points system, and improving response times. The Tracktherm® insulating strips are simply clipped into place over the rail and heating electrode, eliminating heat loss, and energy from the electrode is thereby dissipated quickly and effectively into the rail.

Independent tests show that without Tracktherm insulating strips fitted localised heating of the rails occurs close to the heating element, without heat retention and heat flow through the rail. When Tracktherm is applied homogenous heating ensures that the entire rail is heated to a temperature equivalent to 300C.

The resulting improved heating of the rail leads to faster response, higher rail temperature and reduced energy use. Energy consumption can be improved by 25-30%, and the response time to heat a standard set of points reduced from around two hours to approximately 50 minutes. As a result, rail infrastructure managers could choose a lower power-rated heating electrode to reduce the energy consumption or include heating systems where previously insufficient power was available.

This has a big impact on the performance of the whole points heating system and saves energy costs. In the same installation, a 200W/m heating strip would consume more than 0.5kWhr/m of points heated in energy, in order to heat and subsequently maintain the system at a temperature of about 3 degrees C. With the heat retainer fitted, the energy reduction to heat, and similarly maintain the system reduces by more than 25%.

Maximising the benefits for line maintenance

The true benefits of incorporating Tracktherm insulating strips into the rail network are not limited to new points heating system installations and upgrades, but can be quickly and easily applied during planned maintenance programmes, enabling networks to run more efficiently and effectively all year round.

Installations using Tracktherm have been successfully completed throughout the UK and Denmark. Tony Jackson, Senior Reliability Improvement Specialist – Track & Lineside at Network Rail commented “In the 3 years that Network Rail has been supplied insulated products from the Proctor Group; I have been impressed at their ability to grasp a new market sector. Whilst the Proctor Group is not a multi-national organisation; this is actually a strength as they react more quickly to the need of the customer. During 2012/13 Network Rail delivered a project to improve the points heating; with 2,250 point ends being fitted with heat retainers. 80% of these points were installed with the Proctor product.”

Looking further down the line, the A. Proctor Group, renowned for providing high quality, technically advanced thermal, acoustic and membrane products for the construction industry is expanding its portfolio for the rail industry. A number of new innovative solutions are coming including coatings, which will provide anti-corrosion protection, which will protect and extend the lifespan of rails, and coatings which can reduce the heat build of continuously welded rails so that summer buckling can be avoided during periods of high temperature. These products will be key to helping rail engineers address the challenges of maintaining an efficient rail network and keeping Britain’s economy on track.