For example, no one would argue that a heavy knitted jumper will keep you warm, but up a mountain in a howling gale, the wind will blow right through it, rendering its high insulation levels ineffective. Adding an oilskin jacket will block the wind very effectively, however after walking up the mountain, it’s limitations as regards breathability will become all too apparent. A Gore-Tex jacket on the other hand, being both air tight, water resistant and vapour permeable, will maximise the effectiveness of the woolly jumper without any of the unpleasant sweatiness of the oilskin. In this example air openness would not be an advantage as it would not deflect the wind as required.

The behaviour of the building envelope is no different, and BS5250 defines the following-

· Airtight layer- prevents the movement of air which may/ may not act as a Vapour Control layer

· Vapour Control Layers- a material which can limit both movement of vapour by diffusion, and air movement (sometimes called vapour checks or vapour barriers)

· Breather Membrane- defined as a membrane with a vapour resistance less than 0.6 MNs/g (sometimes this terminology is used, arguably wrongly ,in place of LR underlays

· HR underlay- an underlay with a vapour resistance greater than 0.25 MNs/g

· LR underlay- an underlay with a vapour resistance less than 0.25 MNs/g (sometimes referred to as vapour permeable or vapour open underlays and some may possess a degree of air permeability)

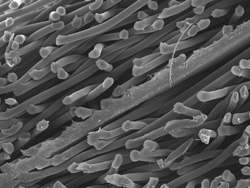

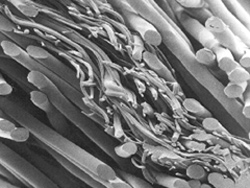

Microscopic photographs below show the difference in the make-up of two types of LR underlays. The one on the left is a vapour permeable/ airtight layer of which there are more than 20 in the UK with BBA certification. The membrane on the right is both air and vapour permeable thus meeting the NHBC requirements for non-ventilated cold pitched roofs.

This terminology, while trying to be helpful can further confuse users. The old ethos of Build tight, ventilate right is a good start but does not tell the whole story. By “ventilate” we mean ensure the buildings internal environment is maintained at healthy levels and there is fresh air movement in a controlled manner. Air infiltration should be limited to designed inlets, not unplanned leakage.

The UK construction sector generally build with air tight layers internally which are also designed as vapour control layers, so as we move through the element from inside to out we generally try to reduce the vapour resistance. A popular example of this is in UK cold pitched roofs where we attempt to make the ceilings as air tight as possible (sometimes with the use of vapour control layers) to improve the thermal efficiency. Outside this airtight layer, above the thermal insulation, we will either ventilate the roof or use vapour permeable membranes allowing potentially harmful vapour to escape prior to condensing. The NHBC have given further guidance that even when using vapour permeable membranes, LR type, you should still provide high level ventilation, however they further state that if the vapour permeable membrane is also AIR permeable, this additional ventilation is unnecessary.

This is based on evidence showing the air permeability of the underlay lowers the risk of condensation further, as in addition to vapour escaping by diffusion, a substantial air change rate is also achieved via the air permeable membrane, as much as would be achieved with traditional ventilation. So in this situation it can be advantageous for the membrane to be both vapour AND air permeable as opposed to air tight.

This has taken the UK industry over 15 years to embrace, proof that we need to be more adaptable and open to changing techniques and requirements. The days of “if my grandfather never used it, I don’t want to” are hopefully becoming a thing of the past.

In North America the issue of air tightness is crucial in the design of thermally efficient buildings not only to reduce heat losses but to reduce air conditioning/cooling costs. Here it is common to use an AIR TIGHT vapour permeable membrane on the walls to reduce unwanted air infiltration. The membrane reduces the movement of unwanted external air yet ensures the risk of condensation is kept to a minimum by maximising the vapour permeability. Installing the AIR tight layer externally ensures continuity is not interrupted by floor and ceiling joists, and subsequent trades damaging the air tight layer. New technologies have shown that vapour permeable air tight layers can prove cost effective externally in walls, so perhaps it is time for the UK to learn from this and install our air tightness measures externally.

The A Proctor Group, with a highly trained experienced technical team of 5, can advise building professionals of which membranes to use in order to achieve thermally efficient, healthy buildings.

New technology is constantly evolving the way we can meet the requirements of ever changing regulations and thermal insulation. By embracing this innovation the building professional will meet his clients’ demands with easier to install cost effective measures.

| Product | Vapour | Air | Application | Link |

| Proctor Air | Vapour Permeable | Air Tight | Air and vapour permeable, highly water resistant roofing underlay | More Info |

| Wraptite | Vapour Permeable | Air Tight | External air barrier – used outside the services zone | More Info |

| Frameshield 100 | Vapour Permeable | Air Permeable | Breathable walling membrane | More Info |

| Procheck 300 | Vapour Tight | Air Tight | Lightweight vapour barrier used internally | More Info |

| Procheck 500 | Vapour Tight | Air Tight | Standard vapour barrier used internally | More Info |

| Profoil 861 | Vapour Tight | Air Tight | High performance reinforced vapour barrier | More Info |

| Reflectatherm Plus | Vapour Tight | Air Tight | Reflective vapour barrier that increases thermal performance | More Info |

| Proctorwrap Reflect | Vapour Permeable | Air Permeable | Reflective breather membrane that increases thermal performance | More Info |

| Cladshield | Vapour Permeable | Air Permeable | Breathable membrane for lightweight industrial roofing and walling | More Info |

Webinar Transcript

Good afternoon. My name is Keira Proctor and I’m the Managing Director here at The A. Proctor Group. I’m going to be talking you through our webinar today ‘Membranes Explained’, which will be followed by a question and answer session with our technical director Iain Fairnington. So please feel free to type any questions you may have along the way and Iain will be able to answer these at the end of the session.

Lastly, and please bear in mind that, when we’re talking about these membranes and the placement of the membranes we’re discussing them within the UK climate or certainly climates which are heated rather than cooled.

The first thing to consider is the construction membranes perform a variety of important functions within the building envelope. These membranes are a relatively recent addition to building design. However, the pace of technological improvement and the rate of adoption of such membranes is arguably faster than any other construction technology. With performance requirements of both the membrane and the building in which they are used improving all the time it’s absolutely crucial to ensure correct materials are specified.

Okay so, BS 5250 is the code of practice for the control of condensation in buildings. What this does is outlines where and when the membrane should be used along with the ventilation requirements that may apply. BS 5250 actually defines the various types of condensation control membranes.

Airtight Layer

A layer which prevents the convective movement of air under the normal pressure differences found in buildings and which may also act as a vapour control layer.

Breather Membranes

Membrane with the vapour resistance of less than or equal to 0.6 MNs/g.

Type HR underlay

Also known as a high-resistance underlay which has a vapour resistance greater than 0.25 MNs/g

Type LR Underlay or low resistance underlay

Underlay which has water vapour resistance less than or equal to 0.25 MNs/g

Vapour Control Layers

Material for construction that substantially reduces the water vapour transfer through any building on which it is incorporated by limiting both vapour diffusion and air movement.

The industry has a responsibility to ensure these membranes are not only up to the required specification but they’re used in the correct position within the building. By ensuring the correct position you can ensure that they’re performing the functions that they have been designed for. Breathable membranes are installed on the outside of the insulated envelope and what this does is allows the membrane to provide temporary weather protection during the construction and then secondary protection once the building is actually complete. These membranes generally contain something called a hyrdrophobic additive and basically what that means is that they actively repelling liquid water. The vapour permeable nature of the breather membranes they actually ensure that any moisture that’s within the construction or that originates within the building, so that could be the building use or occupants and allows it to escape through the atmosphere as easily as possible.

Insulation prevents heat loss from the building envelope. However, if the specification has not been carefully considered, so for example it’s not thick enough or it’s not being placed in the in correct location, this could lead to moisture vapour beginning trapped in cold areas and that then can lead to condensation.

A vapour control layer is installed internally and what it does is help prevent any condensation or moisture vapour actually entering the roof or wall construction. So in addition to ensuring these membranes are in the correct position and you’re comfortable with that it’s very important not to forget that they also need to have the correct technical performance. In terms of composition breathable membranes are typically engineered plastics known as polypropylene or polyethylene.

I covered briefly the definitions under BS 5250 a little bit earlier and what BS 5250 defined was that breathable membrane requires to have a vapour resistance low 0.6MNs/g. However, it’s important to remember that for roof applications it has to be 0.25MNs/g or lower.

Once you’re taking a breathable membrane to be used in a roofing application you’ll hear the terminology change slightly, and they’re generally referred to as a vapour permeable underlay or VPU. Roofing breathable membranes or vapour permeable underlays can be airtight or air open and what that will have an effect on is the amount of ventilation or if ventilation is required on that particular roof.

So in the UK these membranes are always used on the cold side of the insulated envelope, so meaning it’s always on the external side of the insulation product.

Vapour Control Layers are generally made of polyethylene that could be unreinforced or reinforced depending on the application. If a much higher performance is required and it can be supplemented with a layer of aluminium which gives a much higher vapour resistance. The performance required from these vapour control layers is much more closely linked to the building usage than the case for breather membrane. So essentially, depending on how much vapour is going to be generated within a particular dwelling or building will dictate the performance of the vapour control layer requires to have. For example, for applications which are less humid, so perhaps the warehouse or an industrial unit, they’ll typically use VCL’S with resistance around 125-250 MNs/g but then you’ll have a high risk application, perhaps a swimming pool, and they will incorporate the aluminium foil like I spoke about earlier and they might require resistance as high as 44,000MNs/g. And the vapour control layers can be the complete opposite to breathable membranes are always installed on the warm side of the heated envelope, therefore, on the inside as to where your installations being placed.y

So while there is a degree of overlap in the functions of the various types of these membranes the differences between them are significant and this of course is going to have an effect on how they’re being used. The composition of an air permeable membrane is a core layer of melt blown polypropylene which is sandwiched between two layers of spun bond polypropylene. It’s these outer layers that help provide additional water resistance and it also protects the core from physical damage. It might be hard to picture but the actual fibres in the melt blown core are hundreds of times smaller than a human hair and what this does is gives the membrane a microporous structure, which means that allows water to pass through as vapour but not as liquid. So the open nature of air permeable membranes therefore allows air movement through the membrane and that in turn boosts the rate at which vapour can escape a roof, and what that does is significantly reduces the risk of condensation occurring in the roof.

Film laminate membranes instead of using a melt blown core they use a film core in the centre of the product. Similarly to air permeable membranes the film in the centre is sandwiched between two carrier layers and, as before, what these outer layers do is provide additional water resistance and they protect the core from any damage. The water hold-out properties of this film core, generally mean that these membranes are typically offering higher levels of water resistance, than the air permeable materials. However, that does come at the expense of the greatly reduced vapour permeability.

The good news is in comparison to the breathable membranes vapour control layers are relatively simple. Most vapour control layers are polyethylene or aluminium and none of them have perforations and what that does is ensures that the vapour resistance and air tightness of the product is maximized.

When it comes to vapour control layers, reinforced membranes are generally preferable. So basically the performance of the membrane is only as good as its continuity, unreinforced membranes can tear and stretch unless care is taken during installation.

This diagram shows the traditional type of roof construction which is using a type HR underlay as I defined earlier in BS 5250. So this type of underlay includes traditional bitumen roofing felt as well as a more modern plastic equivalent. Due to the nature of the type HR underlay it means that vapour can’t escape through the membrane at all. Therefore, it has to be removed from the roof by means of ventilation openings. So, the exact specification of the ventilation may vary but typically vent openings are provided at the eaves of the roof and then again at the ridge. While this method is effective and it’s been proven over a long period of time the roof is actually susceptible to vents becoming blocked. So for example items could be stored in a loft and certainly for more complex roof configurations you must ensure that there’s adequate air flow throughout and that can be quite challenging.

So coming onto airtight LR underlays or low resistance underlays they can improve the situation by essentially allowing the vapour to escape through the entire roof surface and not just through the ventilation openings. So whilst this reduces the likelihood of the vents becoming blocked airtight LR underlays do not have sufficient vapour permeability to eliminate the need to ventilate all together. Now that’s particularly true during the initial phase after construction and at this point there’s a significantly higher moisture load from wet trades etc. and this is known as the drying out period. It’s, therefore, very common to see airtight LR underlays requiring 5mm of ridge ventilation and that assists in the removal of vapour they also usually require the ceiling to be very well sealed. Or certainly a vapour control layer to be used at ceiling level.

By providing, to quote the BBA, a significant additional mechanism for water vapour egress by convection, air permeable membranes can always be used with no additional ventilation as both air and vapour can move freely throughout the entire roof surface. So essentially the additional benefits of air permeability mean that no vapour control layer is required at the ceiling level and no openings are required at the ridge. This type of roof construction provides a much more simple and more robust solution meaning there’s less likelihood of incorrect ventilation or ceiling specification or issues with installation. As long as the air open underlay is installed currently the risk of condensation will be minimal and that’s going to be throughout the whole lifetime of the building.

Where the more recent construction membrane developments is the use of external air barrier membranes and this represents quite a significant departure from the accepted traditional practice. However, having a membrane which is highly vapour permeable but also acting as an external air barrier level seems to be quite a comprehensive way of achieving the buildings are tightness strategy.

I spoke earlier about vapour control layers and the placement on the internal side of the insulation traditionally being vapour and airtight has performed a function of the airtight layer within a dwelling or building.

Whilst a solution does work, it does place a lot of emphasis on the quality of installation and sealing of the internal vapour control layer and which can be difficult and can be expensive, and it can be very time consuming. By moving the airtight layer to the outside of the heated envelope, and again I mean on the external face of the insulation, it presents a much quicker, a simpler way and a more robust solution because you’re taking the airtight layer away from any service penetrations and areas where it may be punctured during installation. So again it seems to be a much better airtightness strategy.

Nearly all vapour control layers can be used as the internal air barrier membrane; so that simply means that the membrane which is used internally is both air and vapour tight. On the external side, however, not all vapour permeable membranes are suitable, so for example an air permeable breather membrane would allow air leakage which would not help the energy efficiency of the building. What we see now is more mechanically fixed external air barriers, however, there are more advanced membranes today some which have self -adhered characteristics which allows for a more continuous external air barrier whilst remaining breathable. When using membranes of this type is really important that vapour control is very carefully considered, it might be necessary to limit moisture vapour transfer, for example, using a well-sealed vapour tight insulation board.

The main benefits of an external air barrier comes in the installation process and the robustness that it then adds when it’s insitu. So if you have a look at internal air barriers they are required to be sealed around all service penetrations, structural elements and openings throughout the structure or the wall which adds considerably to the time and cost of the installation process.

Each of these seals represents a potential point of failure for the internal airtight layer. Now the issue with that is that it may not be discovered until the membrane’s covered by internal decorative finishes, and that makes your mediation complex and it makes it expensive. But most importantly failure to meet the designed air leakage rates can have a major effect on the energy performance of the building. So moving the air barrier or airtight layer externally usually reduces the amount of sealing required and that increases the likelihood that the air leakage targets will be met.

Basically this allows use of more ambitious air leakage rates at the design stage giving improved design flexibility in other areas such as thermal insulation.

The effectiveness of these external air barrier systems has now actually been demonstrated on a lot of projects throughout the UK. One example of this is the Anchorage Children’s Home which was built for Hampshire County Council. So achieving a low level of air leakage was an important part of the energy performance strategy for this particular building, and in order to achieve this and what the contractors Raymond Brown did was turned to Wraptite SA which is an external air barrier which we supply. So what the Wraptite SA does is combines very high vapour permeability with low air permeability and because it’s actually self-adhesive it allows for a quick and simple installation process on or off-site.

So, although this building looks quite traditional in its outward appearance it actually uses very high-tech structural insulated panels, or otherwise known as SIPS. So the performance of these panels along with the 0.5 air changes per hour air leakage rates provides a very highly efficient envelope which in turn then delivers very low running costs over the life cycle of the building.

So these panels were fully wrapped with Wraptite SA vapour permeable membrane and at the joints the tape version of this product is used to seal any junctions openings, services and what that does is ensures an entirely airtight envelope without leading to any issues, for example, with trapped moisture. So as I explained earlier the 0.5 air changes per hour air leakage target when they tested this project it actually delivered the first time pressure test comfortably of 0.43 air changes per hour. So, as I said, are comfortably under where they set the initial target. More impressively this air leakage result was achieved prior to installing our Procheck 500 vapour control layer on the warm side of the insulation. Although the vapour control layer is not necessarily required as part of the air barrier system they may still be needed to control moisture ingress dependent on the precise specification of the construction. So we would always recommend an expert Hygro Thermal assessment be undertaken to verify this.

Building regulations compliance in the UK is assessed via the carbon emissions a building produces. So if you take domestic buildings as an example this is called the Dwelling Emission Rate commonly known as the DER. To explain the DER in a little bit more detail, basically it’s holistic value which incorporates the effects of all the energy performance measures which are included in the building design. So it allows characteristics for example air leakage rates, thermal insulation levels, areas of glazing or renewable energy sources like PV panels to be considered within the overall energy performance of that dwelling. So looking at this example here achieving a 6% improvement in DER means increasing the thickness of insulation from 130mm to 360mm which is going to have a significant effect on the building footprint or the internal space and that’s not even thinking about the cost it’s going to incur. In contrast by improving the air tightness of the dwelling the insulation thickness can actually remain unaffected. So if you can take the pressure test from 7 down to 1, this results in the same 6% improvement in DER. Fair to say that with the latest generation of self-adhesive external air barriers this degree of improvement isn’t difficult to achieve. It’s going to be highly cost effective compared to adding over 200mm of extra insulation.

So, if I can just try to summarize very quickly, and I understand has been a lot to take in during this webinar, essentially there is a ton of differences in the performance characteristics between the different types of membrane. What’s important is ensuring the correct membrane specification is used and that it’s being used the correct position and its effect on the whole building envelope is being considered. All of these are very important aspects of the design process.

What I’d like to do now is pass over to Iain Fairnington who is Technical Director here at the A Proctor Group. He’ll be able to answer any technical questions, queries or general comments that you may have.

Thank you.Good afternoon everyone.

Hopefully you can all hear me. My name is Iain Fairnington and I’m the Technical Director of the A Proctor Group. I sit on a number of British Standards including the Control of Condensation and BS5534; the code of practice for roofing.

I know there’s lot of information for you to take in but don’t worry a replay pack will be sent to everyone who registered for the webinar.

We had a few questions submitted by email prior to the webinar starting and also a very interesting comment about kagools from Donald I think, so thank you for that. If anyone does have any questions they want to type feel free, and of course you’re welcome to listen to existing questions that we have. Alternately you can always contact our offices at a later date, we’re more than happy to help out.

One of the first questions that we had, Iain, was regarding the use of a membrane behind rainscreen cladding, or is it sufficient just to tape the joints with the breathable tape?

Thanks, Keira.

Yes traditionally it’s used a breather membrane within the cavity of rainscreen cladding. However, the introduction of the vapour permeable Wraptite Tape has allowed for the taping of the insulation boards, purely just the joints, which has provided a lot of advantages without membranes hanging in the cavity, and potential fire risks. Especially over 18 meters the BRE have done some work with us to assess the fire risk of the Wraptite Tape used in this application over 18 meters with insulation boards and they have confirmed that they are comfortable with the use of the tape, purely the tape behind the rainscreen cladding in this application.

Ok. Another question we had was regarding the use of ventilation with air permeable membranes and obviously we covered that during the seminar but there was a question as to how you can prove that no ventilation is required with these types of membranes?

So this question is related to the use of air permeable membranes within cold roofs without insulation. There’s been a considerable amount of work carried out over the recent years with membranes and a lot of debate regarding whether you need to ventilate these cold pitched roofs or not. There have been a lot of people saying that by using a vapour permeable membrane you don’t need to ventilate these roofs. However, it still has some limitations on a vapour permeable membrane and what seems to have come out of this research is the benefits of air permeability along with vapour permeability. To the extent where even the NHBC now accept that an air permeable, Vapour permeable roofing underlay does not require ventilation, but any air tight permeable membrane will still require some ventilation at the ridge which is linked to a lot of advantages for the house builder being able to completely clad their roof with the membrane without any water penetration at the ridge where it’s been left so that air permeable membranes in this application show considerable advantages in the home building market.

A quick one here does Wraptite SA stick to block work? The Wraptite SA was obviously the external self-adhesive vapour barrier that I explained earlier in the webinar.

Again another very good question with any adhesive, the substrate is very important. Whether it be wet or dusty will affect the ability for any adhesive to adhere. With Wraptite in particular a primer’s not required as long as the surface substrate is clean and dry and we advise in our installation guide how to achieve that. So yes, it can stick to the masonry very effectively if the conditions are favourable.

Jumping to a quick question about software. Are you finding much difference in results when using WUFI modelling instead of Glazer?

The Glazer method has been very successful for many years and the A Proctor Group have been able to provide condensation control calculations for a number of years using the Glazer method. However, it does have limitations, its steady-state only looks at movement in one direction, moisture movement in one direction, it doesn’t take into consideration driven rain or indeed absorption or porosity. The A Proctor Group have invested heavily in the technology of WUFI modelling, where all our technical people can carry out WUFI calculations which significantly adds to the dynamic nature of the condensation calculation. We can take into consideration the convection we can put in moisture sources, assuming that there is moisture within the existing building, rather than just assuming its new build. So it’s provided a lot of advantages and it further emphasizes our expertise in this field.

Ok so typed question coming through from Clemont who would like it to be explained again whether there are actually effective airtight membranes which are also be vapour permeable that can be used in a breathing wall?

Ok, yes just for clarity what we are promoting here is a vapour permeable airtight membrane. So what we are providing is a membrane that can be applied to the external envelope that’s vapour permeable, so it reduces the condensation risk by allowing the building to breath but it provides, at the same time, an airtight layer. That obviously affects the energy efficiency , so Wraptite would provide that performance that you’re looking for there, Clemont, in terms of airtight membrane that is vapour permeable used externally for a consistent seal of the airtight membrane.

Iain, this isn’t actually a question, but just on the back of that, can you explain briefly the importance or the requirement for a vapour control layer internally if you’re using an external vapour permeable air barrier.

Yet another very, very good question and one that we have lots of debates on, whether you need a vapour control layer with an airtight vapour permeable membrane. The straightforward answer, or less than straight forward answer is, it depends it on a number of factors in terms of the building wall fabric build-up. The type of insulation is really important. If you’re looking for breathing wall you’re going to be using a an insulation with a high vapour permeability and therefore there’s a higher risk of condensation within that application and therefore it’s more likely that you’re going to need a vapour control layer in that type of construction than a vapour tight insulation of low permeability. But as I said earlier we can calculate that using the WUFI calculation in particular cases.

Ok here we have a question from Mike. If you use an Air Permeable membrane on the roof, how does this affect air tightness?

That’s a very logical question. Using an air-permeable membrane on the roof increases the air permeability of the loft space. The actual air tightness of the dwelling will depend on the surrounding area of the living space. So for air tightness of a dwelling we utilizing a cold roof the sealing is really important and there is many well seald ceilings now that are utilized to provide air tightness of the ceiling as well as the walls and that is in the living space. And that’s the more important place for air tightness when utilizing a cold roof. Anything above the insulation, we believe, it’s more beneficial to be air permeable to reduce the condensation risk to increase the air circulation within that space to keep the building moisture-proof.

Essentially, Mike, if your project was a warm roof you could use a product such as Wraptite SA or film laminate product which was airtight to complete that sort of air tightness.

Here’s another interesting question from Martin about refurbishment. So, when used on an existing listed building and with Hydroscopic Insulation do you need to allow an air gap below the roof BPM and do you need to ventilate above if there is slate?

Ok, one of the main applications or one of the applications that you can utilize and Air Permeable membranes benefits is in the refurbishment market because we specifically don’t require a vapour control layer at ceiling level you do not need to have the refurbishment is not so difficult. A lot of vapour permeable membranes require a vapour control layer to be used at ceiling level and that is really difficult in refurbishment projects.

Just before we go into the next question there’s one for Iain. Could you just clarify for Iain, which application and what type of membrane you’re talking about in that question? If you could type that, that would be great.

The next question from John, asking if we’ve identified any risks or considerations if the Wraptite SA was going to be applied to building undergoing deep retrofit? That’s a good question John. I think we’d need to probably have a more in-depth conversation on what you’re requiring in terms of deep retrofit. Obviously Wraptite can be used in refurbishment projects but it’s more used in new build projects. Depending on the building envelope you can utilize the Wraptite SA internally or indeed if it was in the external insulation you could use it externally prior to putting on the insulation in an external wall system.

Ok. So Ian’s asking question regarding the internal airtight membrane Procheck or Wraptite Yellow or Red, if it’s self-adhered?

So,there are two threads to this question. So I’m just reading through the question. So this is laid to a rough concrete floor sealing the membrane, cables and pipes and using an internal airtight membrane like Procheck. If you’re using internally then you would be using more of a Procheck vapour control layer if it’s in a floor,depending on the application it’s going to be difficult to create complete air tightness in the refurbishment of that. So care would have to be taken sealing the wall and floor junctions. Our Wraptite has been used successfully in that area for draught-proofing on timber floors and they can be used on concrete floor so the junction between the wall and the floor would need to be looked at. If you had a detail of that we would more than happy to a look at that and going into that in a bit more detail.

Just a second question from a Clemont (& I apologise if I pronounced that wrong) So you asked about the original question was regarding an airtight and vapour permeable membrane sort of being the same thing for being available in that function and if you’re commenting here so it’s an insulation material tolerates changes in moisture content then that should be fine. Is that correct?

I think, Clemont, maybe you’re looking at cellulose fibre perhaps? Cellulous fibre can be viewed as moisture tolerant and there has been some very good examples of cellulose fibre used as the insulation and the potential condensation risk and potential moisture management that the cellulose fibre provides, so in that case it might not be as critical to use a vapour control layer because you have a complete breathing insulation that is very effective.

Ok another question from Donald. So when using a warm roof and and Air permeable membrane over sarking, do you recommend loose terminating it into the gutter or do you think we’re moving towards creating continuity with some elements in the wall construction?

Donald it’s obviously tradition to loose-lay the roofing underlay into the gutter as is usual practice. As dwellings strive for more air tightness then that connection can be more complicated and therefore if air tightness is looked for we have obviously the Wraptite Tape BBA for walls. But we also have Wraptite SA used for roofing applications with BBA Certification. Now for those two combined together can make the connection at the eaves a lot simpler because you have continuity of the air tightness in particular where there’s a warm roof used. If it’s a cold roof thenthe detailing of that can be more difficult, but certainly with warm roofs the connection or continuity of the roofing underlay and wall underlay is a lot easier.

Ok a question from William who’s considering using external insulation on a concrete block structure. So the ideal place, he’s saying, for the air barrier would be actually the outside of the block but would the Wraptite SA limit any moisture flow here?

Yeah the utilizing it doesn’t have again depending on the insulation that’s being utilized. If you’re using a low permeability insulation, if you’re using the Wraptite on the external side of things of the block work you get the benefit of water tightness during construction, you get the benefit of a complete airtight membrane or more complete airtight membrane on the outside without as many penetrations. If you are then to put insulation on the top of that was all of low permeability then you are inhibiting the benefit of the Wraptite in terms of its breathability. But utilizing the insulation on the outside the condensation risk would be driven outside the building envelope and many people in the cladding industry are utilizing Wraptite on the sheathing board and then applying the insulation on top of that. So here they get two of the three benefits, water tightness, air tightness but not so much the vapour tightness. But because of the insulation on the outside the condensation risk is taken outside the building envelope and therefore a good application.

Ok and here we go Ian needs a bit further clarification and so if your GPA calculation shows there to be no condensation risk with a rainscreen wall cladding k15 Wraptite SFS is there a requirement for an internal vapour control layer?

Hi there. We can do calculation using GP software which is the Glazer Method and it can show that there’s no risk of condensation. However, a lot depends on the installation of the various elements so the Glazer Method when you put in an insulation board will assume that it is continuous and well installed. So sometimes you have to look at the outputs from these calculations and see whether they are realistic in an actual site application and build-ability. So we would take a judgment on that and would point out to the client whether there was a potential risk if they don’t apply all the elements correctly. More than happy that it could be done if it’s all installed perfect, but we are in the building industry and sometimes in the building industry not everything that was on the drawing board actually happens on site.

This question is about the covering of Wraptite, obviously Wraptite SA which Clemont points out, it does need protection against the elements, therefore final cover cladding etc. Does that limit its use in the Refurbishment of traditional buildings?

Yes if it’s an old historic building then you wouldn’t utilize that on the outside of buildings because you will detract from it’s traditional look. However, if you are over-cladding it in an older building and want to refurbish the look of the building then Wraptite is ok. However, you’re very correct, don’t use it if you don’t want to change the look of the outside in refurbishment.

Thanks Iain, that’s good. So I think that’s all the questions we’ve had and covered the couple we had before the webinar started.

So just really want to thank you Iain for answering the questions and thank you for coming I really appreciate the numbers and hope you all enjoyed it and find it helpful or educational.

We are here, we do have a technical team who can take questions. Iain has a team of five or six who can do drawings & calculations and answer any questions over the phone and you’ll find the details on our website. We will be sending this back out so that you could circulate it to colleagues or potentially look back at areas that particularly interested you.

Sorry just one last question coming from Clemont again in this case can it be used internally instead? That’s a good question.

Yes that’s a good point Clemont you can use it internally instead, again depending on the building fabric but in that refurbishment case where you don’t want to change or compromise the look of the building aesthetically in traditional buildings then yes, you can turn the inside and look to see increases the airtightness from the inside utilizing the benefits of the Wraptite.

A final thank you to Kenny, who’s from our marketing team, sitting next to me very silently. He’s put this webinar together. So as I explained, please contact us and we’ll probably do another webinar in the new year and which we can make and thank you for your time.