Investment in research and development has created an unrivalled portfolio of specialist vapor and airtight membranes, which provide solutions to many of the key challenges posed to the construction sector by energy efficiency regulations such as GBR &Estidama. Consultants and architects receive comprehensive support from project planning through to completion, including region specific Condensation Risk Analysis, BIM objects, comprehensive specifications & installation guidance.

Protection of airport assets: condensation control

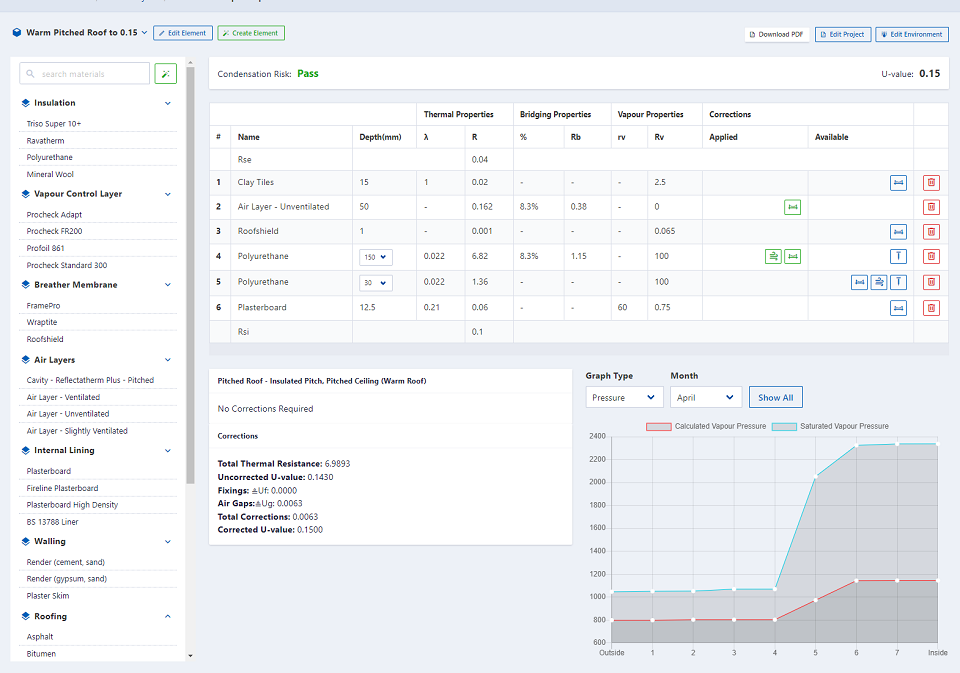

It has long been recognised that the correct management of moisture vapour within buildings is an important aspect of ensuring the longevity of not only the building fabric, but also the health of the occupants. As today’s structures become increasingly better insulated, more airtight, and more energy efficient, taking management of moisture into account in the design process becomes more critical, to ensure that it provides a durable, fit for purpose environment throughout the building’s lifespan. As energy performance has grown to become an important aspect of building design, measures such as heating, ventilation and air conditioning have all come under closer scrutiny. The routes by which airborne moisture vapor an escape are now an essential part of best practice building design. If not adequately mitigated, condensation will occur within the fabric of the wall and roof elements. If left unresolved (or undetected) the resultant liquid water condensation can lead to structural problems such as warping of timber,corrosion of steel,or damage to insulation, decorative finishes and building services. Trapped moisture can also lead to mould growth, presenting a substantial risk to the health of the building’s occupants,and can lead to expensive and complex remedial action. Within an airport environment this can be hugely disruptive,not only to passengers, but also for airlines and retailers, leading to significant additional costs in lost revenue.

Vapor control solutions

The A. Proctor Group’s range of vapor control solutions has been developed to meet the needs of a wide range of building applications and global environments. Offering high performing vapor control layers, these unique membranes have been designed to provide resistance to tears during installation, and throughout the building life cycle, making them more robust than many of the alternative membranes, and ensuring performance, and providing total protection and peace of mind.

Energy efficiency of airport buildings: airtightness

Air leakage through cracks, gaps, holes and improperly sealed elements such as doors and windows can cause a significant reduction in the performance of even thermally insulated envelopes, in some cases reducing their effectiveness by up to 70%. As thermal insulation requirements increase, this reduction in performance is becoming a critical issue; a consensus having emerged in the industry that discrepancies between ‘as built’ and ‘as designed’ performance are largely attributable to uncontrolled air leakage.

Airtightness solutions

The A. Proctor Group’s range of Wraptite external air barriers address the challenge of reliably achieving airtightness in buildings, with a robust two-component solution. This approach saves on both the labour and material costs associated with meeting the demands of modern energy efficiency requirements in commercial and public buildings. Wraptite and Wraptite-SA (self adhesive), combined with Wraptite Tape provide one of the most highly effective,efficient and durable (resists punctures and tears during construction) air barrier systems, optimising the highest levels of energy efficiency in buildings, whilst protecting the fabric of the building envelope.

A Membrane for All Seasons

Whilst the A. Proctor Group Ltd have a wide range of airtight and vapour-tight membranes, we recognise many climates require different functioning membranes. Roofshield is one such membrane. Case Study: Roofshield at the Detroit Metropolitan Airport Detroit Metropolitan Airport is a major international airport in the USA covering 4,850 acres. Roofshield was chosen for the McNamara Terminal, and the Westin Hotel, the only hotel inside Detroit Metropolitan Airport. Supplied by the A. Proctor Group, Roofshield is the best performing breather membrane on the market. Due to the exceptional performance of the membrane, Roofshield fully functions in both warm and cold roofs, without the need for vents or a vapour barrier.